Product Feature

HST single cylinder hydraulic cone crusher is a new type of high-efficiency crusher developed and improved by our company based on the advanced crusher technology of the United States and Germany, combined with more than 20 years of manufacturing experience. The cone crusher integrates hydraulic lubrication, overload protection, maintenance and cleaning, PLC control and other technologies, which can help more sand and gravel yards and mines to improve crushing efficiency and ensure production time.

When HST series single cylinder hydraulic cone crusher works, the motor drives the transmission shaft of the equipment through the belt pulley and V-belt, and the transmission shaft drives the eccentric sleeve to rotate through the big and small bevel gears, and the moving cone makes the rotary swing movement under the action of the eccentric sleeve through the main shaft, so that the moving cone and the fixed cone are sometimes close to and sometimes far away from the mortar wall, and the materials are constantly squeezed in the crushing cavity between the mortar wall and the crusher Impact and crushing, broken material discharged from the bottom.

1、High production efficiency, strong bearing capacity

The efficient operation of the equipment depends not on the optimal design of single components or the improvement of material quality, but on the coordination of the overall structure;

Through the combination of crushing cavity shape, eccentricity and motion parameters, cone breaking can achieve higher production efficiency and better product quality.

Combined with the optimized strength design and high-quality component materials, the bearing capacity of the equipment is stronger, so that the crushing ratio is larger and the passing capacity is stronger.

2. Low maintenance and operation cost

The structure of the equipment is simple, and all maintenance work can be completed after removing the upper rack, which not only makes the inspection and maintenance more convenient, but also makes the maintenance cost lower.

By ensuring that the internal pressure of the crushing chamber is always higher than the external pressure, the dust or other small particles entering the crusher are effectively reduced, the damage to the bearing is reduced, and the maintenance workload is reduced, and the service life of lubricating oil and equipment is extended.

In addition, its design is compact, installation space is easy to move.

3、 Automatic control of production process

Automatic control system provides manual control, constant discharge port control, constant power control and other operation modes for users to choose;

It can continuously monitor the actual load inside the crusher and automatically adjust the equipment, so as to optimize the utilization rate of the crusher and make the crusher play its performance at any working time;

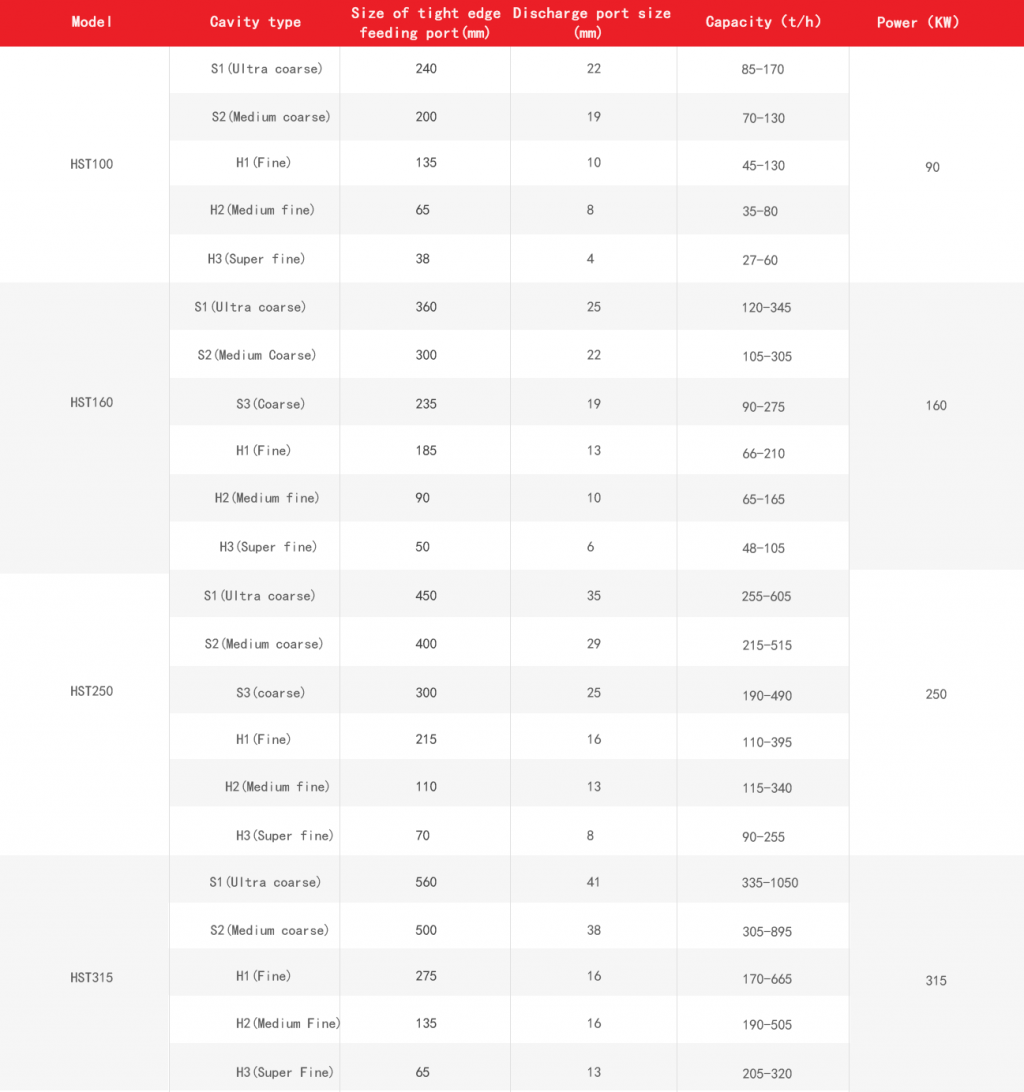

4. The multi cavity type is suitable for a variety of process requirements

The equipment has many kinds of standard crushing cavity types to choose from, and the eccentricity can also be changed flexibly. According to different production processes, suitable crushing cavity and eccentricity can be equipped to meet the crushing requirements.

Product Parameter