Hitachi Mining Excavator & Shovel EX1200-6

Product Feature

Engine

Get more uptime from the efficient Cummins EPA Tier 2 diesel engine that’s one of the most fuel-efficient engines of all, plus is very eco-friendly.

Durable structure and undercarriage

Two grease-filled floating pins, at the boom top and at linkage, increase the sealing ability, extend pin life and reduce repair costs. Wear plates are provided on both sides of a boss at the arm top.

Two grease-filled floating pins, at the boom top and at linkage, increase the sealing ability, extend pin life and reduce repair costs. Wear plates are provided on both sides of a boss at the arm top.

The travel devices are compact-designed to reduce damage for higher mobility, reducing downtime.

The travel devices are compact-designed to reduce damage for higher mobility, reducing downtime.

The center track frame of integral cast steel structure can avoid stress concentration and increase reliability.

The center track frame of integral cast steel structure can avoid stress concentration and increase reliability.

Track links are enlarged to increase strength for higher durability and reliability especially on rugged ground.

Track links are enlarged to increase strength for higher durability and reliability especially on rugged ground.

You get rock-solid durability from a rigid box frame that resists bending and twisting forces, and provides great strength and balance to handle heavy digging and loading jobs.

The EX1200-6 provides you with an upgraded, more brawny undercarriage. The larger diameter swing bearing provides increased reliability and durability, plus improved stability.

Both standard and BE booms have thicker plate steel. The buckets are stronger and larger, and the refined mechanisms produce increased lift capacity and durability.

You can get optional full-length track guards that protect the tracks against rocks and other objects. In addition, wider track shoes and a longer undercarriage frame are available to improve flotation in soft conditions.

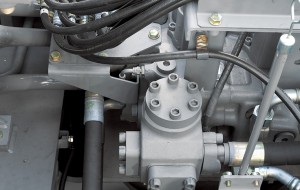

Hydraulics

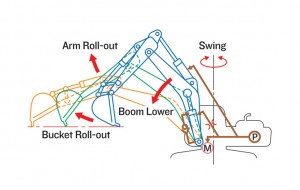

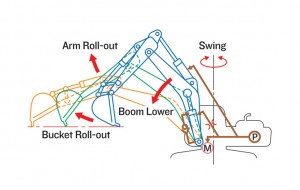

You get flexible boom/swing modes. The boom- or swing-priority mode can be selected for higher production.

When swing angle is small in a cycle of digging, swinging and dumping, boom raise speed increases to reduce a cycle time. When swing angle is large in a cycle of digging, swinging and dumping, swing speed increases to reduce a cycle time.

When swing angle is small in a cycle of digging, swinging and dumping, boom raise speed increases to reduce a cycle time. When swing angle is large in a cycle of digging, swinging and dumping, swing speed increases to reduce a cycle time.

The boom recirculation system efficiently recirculates oil in the boom circuit when the boom lowers, delivering more pressurized oil to the arm to increase arm-lowering speed

The boom recirculation system efficiently recirculates oil in the boom circuit when the boom lowers, delivering more pressurized oil to the arm to increase arm-lowering speed

The oil cooler is separated from the radiator to effectively cool down hydraulic oil. This helps extend the service life of hydraulics.

The oil cooler is separated from the radiator to effectively cool down hydraulic oil. This helps extend the service life of hydraulics.

Simple controls

The color LCD monitor displays operating and machine-event information, which adds to productivity and helps lower downtime with better, on-time maintenance.

The color LCD monitor displays operating and machine-event information, which adds to productivity and helps lower downtime with better, on-time maintenance.

The short-throw pilot control levers provide extremely precise and smooth boom and bucket control, requiring less effort and movement.

The short-throw pilot control levers provide extremely precise and smooth boom and bucket control, requiring less effort and movement.

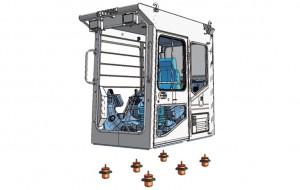

Comfortable cab

The multi-function, multi-language LCD monitor is easy to read and provides key data about the excavator. The Global e- Service mining system uses a data logging unit to record daily operating conditions and warnings. The monitor can be preset to indicate replacement intervals for engine oil, hydraulic oil and filters.

The multi-function, multi-language LCD monitor is easy to read and provides key data about the excavator. The Global e- Service mining system uses a data logging unit to record daily operating conditions and warnings. The monitor can be preset to indicate replacement intervals for engine oil, hydraulic oil and filters.

The standard remote rearview monitoring camera gives the operator wider vision of the work area and eliminates almost all blind spots.

The standard remote rearview monitoring camera gives the operator wider vision of the work area and eliminates almost all blind spots.

The heated, multi-position, air-suspension seat travels 266 mm (10.5 inches), together or independently of the control console, allowing operators to customize their working environment.

The heated, multi-position, air-suspension seat travels 266 mm (10.5 inches), together or independently of the control console, allowing operators to customize their working environment.

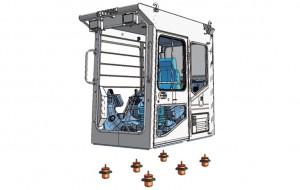

The sturdy cab protects operators from falling objects. The cab’s top guard conforms to OPG Level II (ISO) specifications. The entire cab sits on a package of fluid-filled elastic mounts that reduce vibrations and deliver a more comfortable ride.

The sturdy cab protects operators from falling objects. The cab’s top guard conforms to OPG Level II (ISO) specifications. The entire cab sits on a package of fluid-filled elastic mounts that reduce vibrations and deliver a more comfortable ride.

An optional slide ladder gives the operator even easier access to the cab and working platform.

Easy to maintain

The radiator and oil cooler are arranged side by side to increase cooling efficiency. This also reduces cleaning time and effort.

The radiator and oil cooler are arranged side by side to increase cooling efficiency. This also reduces cleaning time and effort.

The auto dust ejector automatically ejects airborne dust and particles to keep filter elements clean and extend their replacement intervals.

The auto dust ejector automatically ejects airborne dust and particles to keep filter elements clean and extend their replacement intervals.

An air conditioner filter is located next to the cab door behind the operator seat for easy cleaning and replacing.

An air conditioner filter is located next to the cab door behind the operator seat for easy cleaning and replacing.

An electric grease gun (pail can type) is provided standard with a hose reel for convenient lubrication of the swing circle and bucket pin.

An electric grease gun (pail can type) is provided standard with a hose reel for convenient lubrication of the swing circle and bucket pin.

The auto lubrication system is provided standard at the front attachment to simplify daily maintenance, except for the bucket pin and swing circle.

The auto lubrication system is provided standard at the front attachment to simplify daily maintenance, except for the bucket pin and swing circle.

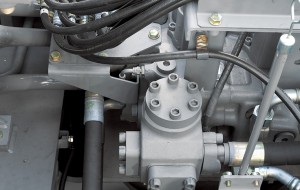

Delivery filters, newly added to the delivery side of hydraulic pumps, effectively protect hydraulic lines from accidents.

Delivery filters, newly added to the delivery side of hydraulic pumps, effectively protect hydraulic lines from accidents.

Remote Machine Management

With Global e-Service, an online machine management system, you can access each on-site machine from a PC in your office. You can get its operating information and location to increase productivity. Operating data and log are sent to a Hitachi server for processing, and then to customer and dealers. This system is available 24/7/365.

Product Parameter

| Emission Rating | Tier 2 |

| Number Of Cylinders - Per Engine | 6 |

| Displacement | 23.15 ltr 1413 Inches³ |

| Rated Speed | 1800 rpm |

| Engine Output Per Engine- Net | 552 kW 740 hp |

| Carrier Rollers - Each Side | 3 |

| Track Rollers - Each Side | 8 |

| Track Shoe Width | 700 mm 28 inches |

| Transport Length | 15970 mm 52 ft 5 in ft/in |

| Transport Height - Maximum | 6860 mm 22 ft 6 in ft/in |

| Overall Width | 5380 mm 17 ft 8 in ft/in |

| Track Length On Ground | 5090 mm 16 ft 8 in ft/in |

| Undercarriage Overall Length | 6500 mm 21 ft 4 in ft/in |

| Tailswing Radius | 4850 mm 15 ft 11 in ft/in |

| Ground Clearance | 1020 mm 40 inches |

| Width over standard tracks | 4600 mm 15 ft 1 in ft/in |

| Track Gauge | 3900 mm 12 ft 10 in ft/in |

| Dig height (mono) | 13460 mm 44 ft 2 in ft/in |

| Dump Height (Mono) | 9080 mm 29 ft 10 in ft/in |

| Max Digging Reach (Mono) | 15350 mm 50 ft 4 in ft/in |

| Ground level reach (mono) | 15010 mm 49 ft 3 in ft/in |

| Dig depth - 2.44m / 8'ft flat bottom | 9260 mm 30 ft 4 in ft/in |

| Dig depth (mono) | 9380 mm 30 ft 9 in ft/in |

| Fuel Tank | 1470 ltr 388.3 gallons (US) |

| Hydraulic Tank | 610 ltr 161.1 gallons (US) |

| Ground Bearing Pressure | 142 kPa 20.6 PSI |

| Dipper Tearout | 430 kN 96668 lbf |

| Weight - Maximum | 111500 kg 245815 lbs |

Two grease-filled floating pins, at the boom top and at linkage, increase the sealing ability, extend pin life and reduce repair costs. Wear plates are provided on both sides of a boss at the arm top.

Two grease-filled floating pins, at the boom top and at linkage, increase the sealing ability, extend pin life and reduce repair costs. Wear plates are provided on both sides of a boss at the arm top. The travel devices are compact-designed to reduce damage for higher mobility, reducing downtime.

The travel devices are compact-designed to reduce damage for higher mobility, reducing downtime. The center track frame of integral cast steel structure can avoid stress concentration and increase reliability.

The center track frame of integral cast steel structure can avoid stress concentration and increase reliability.

The oil cooler is separated from the radiator to effectively cool down hydraulic oil. This helps extend the service life of hydraulics.

The oil cooler is separated from the radiator to effectively cool down hydraulic oil. This helps extend the service life of hydraulics. The color LCD monitor displays operating and machine-event information, which adds to productivity and helps lower downtime with better, on-time maintenance.

The color LCD monitor displays operating and machine-event information, which adds to productivity and helps lower downtime with better, on-time maintenance.

The multi-function, multi-language LCD monitor is easy to read and provides key data about the excavator. The

The multi-function, multi-language LCD monitor is easy to read and provides key data about the excavator. The

The heated, multi-position, air-suspension seat travels 266 mm (10.5 inches), together or independently of the control console, allowing operators to customize their working environment.

The heated, multi-position, air-suspension seat travels 266 mm (10.5 inches), together or independently of the control console, allowing operators to customize their working environment. The sturdy cab protects operators from falling objects. The cab’s top guard conforms to OPG Level II (ISO) specifications. The entire cab sits on a package of fluid-filled elastic mounts that reduce vibrations and deliver a more comfortable ride.

The sturdy cab protects operators from falling objects. The cab’s top guard conforms to OPG Level II (ISO) specifications. The entire cab sits on a package of fluid-filled elastic mounts that reduce vibrations and deliver a more comfortable ride. The radiator and oil cooler are arranged side by side to increase cooling efficiency. This also reduces cleaning time and effort.

The radiator and oil cooler are arranged side by side to increase cooling efficiency. This also reduces cleaning time and effort.

An air conditioner filter is located next to the cab door behind the operator seat for easy cleaning and replacing.

An air conditioner filter is located next to the cab door behind the operator seat for easy cleaning and replacing.

The auto lubrication system is provided standard at the front attachment to simplify daily maintenance, except for the bucket pin and swing circle.

The auto lubrication system is provided standard at the front attachment to simplify daily maintenance, except for the bucket pin and swing circle. Delivery filters, newly added to the delivery side of hydraulic pumps, effectively protect hydraulic lines from accidents.

Delivery filters, newly added to the delivery side of hydraulic pumps, effectively protect hydraulic lines from accidents.