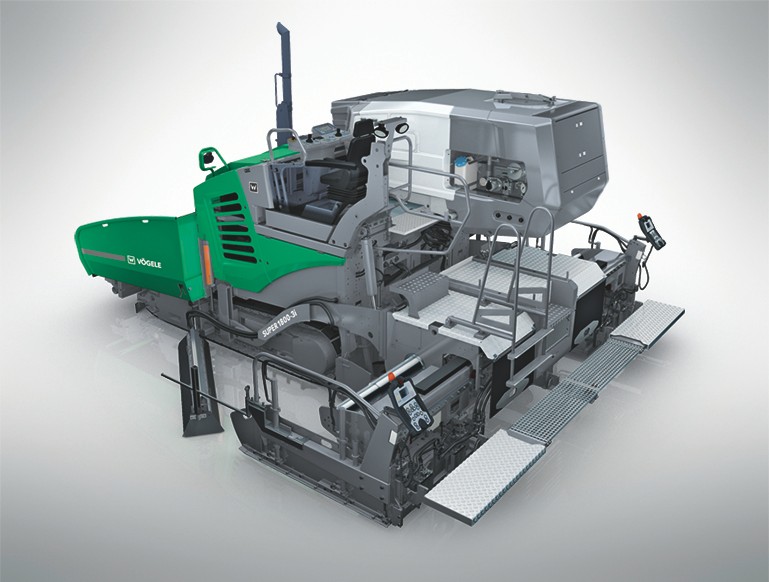

VÖGELE SUPER 1800-3 SprayJet Paver

Weight:

22 tonnes48,500 Ibs.

Width of Spread:

6m19 ft. 8

Rate of Spread:

0.3 - 1.6kg/m²*0.06 - 0.33 lb/ft²

Emulsion Tank:

2,100 litres550 gal. (US)

Product Feature

SUPER 1800-3 SprayJet – The highlights of the new generation

The SUPER 1800-3 SprayJet is ideally suited to paving thin layers on spray seal or for any kind of conventional paving on tack coat.

The SprayJet Module offers a number of advantages from the technological point of view. The rate of spread is infinitely variable from 0.3 to 1.6kg/m2*, thus allowing to spray even small quantities of emulsion. A low spraying pressure of no more than 3 bar reduces spray mist and soiling of adjacent areas to a minimum.

- World‘s unique spray paver for placing thin asphalt overlay as well as conventional binder and surface courses

- “VÖGELE EcoPlus“ low-emissions package

- Uniform “Dash 3” service concept ensures easy maintenance and cuts training costs

- “PaveDock” sprung push-rollers absorb all jolts from the feed lorry

- Emulsion sprayed at a rate of 0.3 to 1.6kg/m²* in a clean and controlled process

- Cutting-edge ErgoPlus 3 operating concept for paver and spray module

- “AutoSet Plus” automatic functions for rapid relocation on the job site and storing paving programs

- ErgoPlus 3 screed console with “Smart Wheel” for convenient adjustment of the screed width

- Ultramodern and precise screed technology

Product Parameter

| SUPER 1800-3i SprayJet | SUPER 1800-3 SprayJet | |

| Engine | 6-cylinder diesel engine, liquid-cooled6-cylinder diesel engine, liquid-cooled | 6-cylinder diesel engine, liquid-cooled6-cylinder diesel engine, liquid-cooled |

| Manufacturer | CumminsCummins | CumminsCummins |

| Type | QSB 6.7 C164QSB 6.7 C164 | QSB 6.7 C170QSB 6.7 C170 |

| Emissions Standard | EU Stage 4, US EPA Tier 4fEU Stage 4, US EPA Tier 4f | EU Stage 3a, US EPA Tier 3EU Stage 3a, US EPA Tier 3 |

| Output | - | - |

| Nominal | 125kW / 2,000rpm170 hp / 2,000 rpm | 127kW / 2,000rpm170 hp / 2,000 rpm |

| ECO Mode | 121kW / 1,700rpm165 hp / 1,700 rpm | 116kW / 1,700rpm156 hp / 1,700 rpm |

| Fuel Tank | 300 litres79 gal. (US) | 300 litres79 gal. (US) |

| Crawler Tracks | provided with rubber padsprovided with rubber pads |

| Ground Contact | 2,830mm x 305mm |

| Track Tension Adjuster | spring assemblyspring assembly |

| Track Rollers | lifetime grease lubricatedlifetime grease lubricated |

| Traction Drive | separate hydraulic drive and electronic control provided for each crawler trackseparate hydraulic drive and electronic control provided for each crawler track | Speeds |

| Pave | up to 24m/minup to 79 fpm |

| Travel | up to 4.5km/hup to 2.8 mph |

| Hopper Capacity | 13 tonnes28,660 Ibs. |

| Width | 3,265mm |

| Feed Height | 594mm (bottom of material hopper)23 in. (bottom of material hopper) |

| Push-Rollers | oscillating, displaceable forwards by 75mmoscillating, displaceable forwards by 4 in. |

| Conveyors | 2, with replaceable feeder bars, conveyor movement reversible for a short time2, with replaceable feeder bars, conveyor movement reversible for a short time |

| Drive | separate hydraulic drive provided for each conveyorseparate hydraulic drive provided for each conveyor |

| Speed | up to 33m/minup to 108 fpm |

| Augers | 2, with replaceable auger blades, auger rotation reversible2, with replaceable auger blades, auger rotation reversible |

| Diameter | 400mm16 in. |

| Drive | separate hydraulic drive provided for each augerseparate hydraulic drive provided for each auger |

| Speed | 84rpm84 rpm |

| Height | infinitely variable by 15cm, hydraulic (lowest position 10cm above the ground)infinitely variable by 15cm, hydraulic (lowest position 10cm above the ground) |

| Lubrication | centralized lubrication system with electrically driven grease pump for conveyor and auger bearingscentralized lubrication system with electrically driven grease pump for conveyor and auger bearings |

| Emulsion Tank | heated electrically, regulated by thermostatheated electrically, regulated by thermostat |

| Holding Capacity | 2,100 litresHolding Capacity: up to 2,000 litres |

| Tank Shell: insulated against loss of heatTank Shell: insulated against loss of heat | |

| Spray Bars | Width: extending from 2.55m to 6mWidth: extending from 8 ft. 2 in. to 19 ft. 8 in. |

| Number of Units: 5Number of Units: 5 | |

| Distance between Nozzles: 250mmDistance between Nozzles: 10 in. | |

| Spray Nozzles | double-slotteddouble-slotted |

| Rate of Spread: 0.3 to 1.6kg/m²Rate of Spread: 0.2 to 1.6 kg/m² (*) | |

| Spray Cone: 120°Spray Cone: 120 ° | |

| Spraying Pressure: 3 bar (max.)Spraying Pressure: 3 bar (*) | |

| AB 500(TV, TP1) | |

| Basic Width | 2.55m |

| Maximum Width(TV, TP1) | 8.5m |

| Maximum Spray Width(TP1, TV) | 6m |

| AB 600(TV, TP1) | |

| Basic Width | 3m9 ft. 10 in. |

| Maximum Width(TV, TP1) | 9m |

| Maximum Spray Width(TP1, TV) | 6m |

| Length | tractor unit and screed in transport positiontractor unit and screed in transport position |

| AB 500(TV) | 6m |

| AB 500(TP1) | 6.13m |

| AB 600(TV) | 6m |

| AB 600(TP1) | 6.13m |

| Weight | tractor unit with screedTractor Unit with Screed |

| AB 500(TV) | 22 tonnes48,500 Ibs. |

| (with AB 500 TV and SprayJet module, no emulsion)(with AB 500 TV and SprayJet module, no emulsion) |