ACE Group Official IAM 80 Model 60-100 t/h Super Mobile Asphalt Mixing Plant For Sale (Customization)

Product Feature

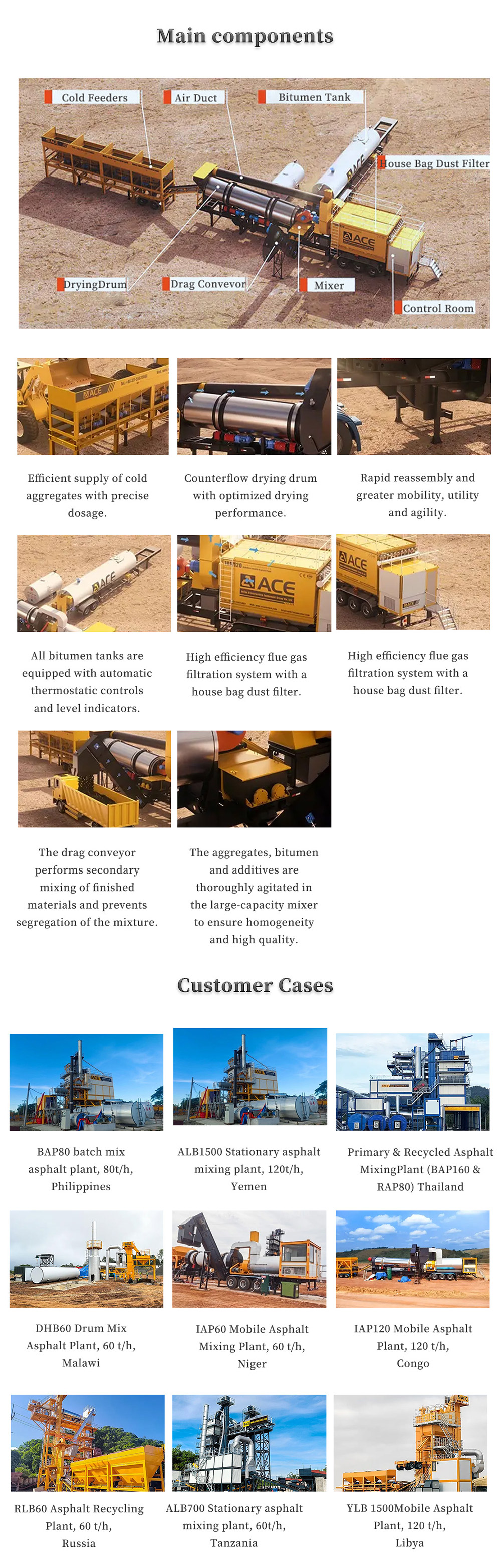

Product Introduction

Our independently developed IAM series super mobile asphalt mixing plant has excellent mobility, dust filter performance and can produce various types of high-quality asphalt mixtures. It is cost-effective, beneficial to the environment and the society. It is widely applicable and owns a long service life.

The IAM series super mobile asphalt mixing plant is integrated into one or two mobile units, which facilitates quick relocation and reassembly can be completed within hours. Only a small amount of foundation construction is required. It is the ideal choice for medium and high-end long-distance road construction projects and is currently popular in markets such as South America, the Middle East and Southeast Asia.

Main Features

1. The plant uses a unique super-mobile modular design, which facilitates transportation and reduces relocation cost. It can also greatly reduce the need for basic civil engineering and labor. At the same time, the assembly time is greatly compressed and practicality is improved.

2. The plant has a small footprint and a mobile chassis with a compact design, which increases flexibility and makes it no longer a challenge to operate in tight spaces.

3. The plant comes standard with 4 cold aggregate silos, which can be added as needed. The feeding speed of the cold feeder can be adjusted by frequency converter to achieve different ratios. A weighing sensor can also be selected to achieve more precise proportions.

4. The feeding opening of the cold aggregate silo is expanded. The sand silo is equipped with a standard automatic silo wall vibrator, and other silos can be equipped as needed. A vibrating screen can also be selected.

5. The front smoke box of the drying drum is designed with a higher height to slow down dusty combustion gases and prevent larger dust particles from entering the exhaust system. This reduces the load on the dust filter bag and prolongs its life.

6. The plant uses an external mixer, which can produce aggregates continuously and improve production efficiency. It also mixes the aggregates more completely and uniformly than the internal mix in the drying drum.

7. The plant uses a house bag dust filter with a filtering area of up to 456㎡. This ensures that the particle emission is less than 50 mg/μm³. The coarse ash collected by the dust collector can be reused in the mixer, and the fine ash can be discharged externally or reused in the mixer.

8. The plant has two modes of operation: automatic and manual. It is simple and flexible to operate. The control system can be accessed, diagnosed and updated remotely.

Product Parameter

Product Model | IAM80 |

Production capacity | 60-100t/h |

Total Power | 127kW |

Total Weight | 55t |

Cold Feeder | |

Cold Feeder Capacity | 9m³ |

Weighing System | Optional |

Hopper Wall Vibrator | 2 |

Aggregate Belt Width | 500mm |

Conveyor Belt Width | 650mm |

Drying Drum | |

Dimensions | Ø1500X7175mm |

Burner | |

Model | EFC1000 |

Mixer | |

Mixing Capacity | 100t/h |

House Bag Dust Filter | |

Number of House Bags | 420 pcs |

Filtration Area | 325m³ |

Filtration Efficiency | 99% |

Particle Emissions | 50mg/μm³ |

Cleaning Mode | Pulse Jets |

Scraper Conveyor | |

HMA Storage Silo | 1.55m³ |

Mobile Chassis | |

Suspension/Brakes | Air Brakes |

Axles/Tires | 2/8+3/12 pcs |

Cold Feeder Specifications | |

Length | 14,505mm |

Width | 2,750mm |

Height | 3,415mm |

Drying Drum Specifications | |

Length | 20,740mm |

Width | 3,267mm |

Height | 4,395mm |