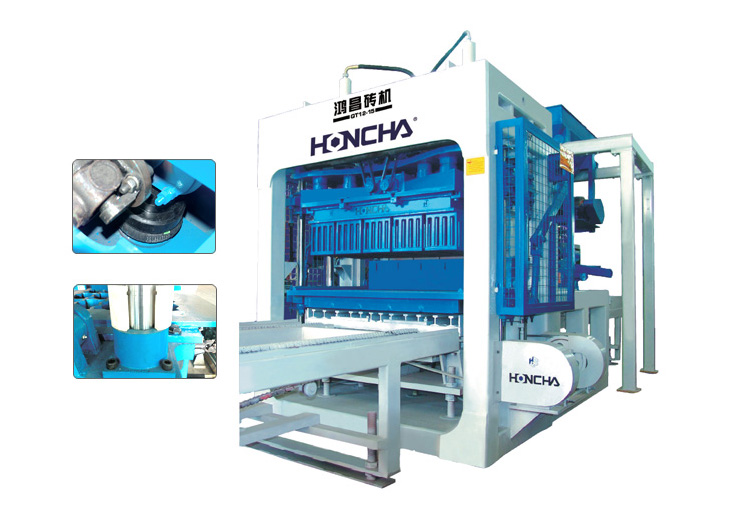

Product Feature

1. The new feeding hopper can quickly and evenly feed the material into the mould, and the distribution is more uniform. New type feeding trolley equipped with wear-resistant and leak-proof device.

2. By adopting frequency conversion synchronous vibration mode, the vibration frequency can be adjusted according to different technological requirements, so as to realize low frequency feeding and high frequency forming, greatly improve the quality and output of products, effectively extend the service life of mould and reduce the cement consumption.

3. Equipped with energy-saving vibrator, it can effectively and accurately control the height of products and reduce energy consumption.

4. Fast moulds changing system ensures that the moulds can be replaced quickly and the vibration platform can be debugged to meet the needs of customers in diversified production.

5. Multi-purpose machine, various concrete block products can be produced by changing moulds, high production efficiency and low maintenance rate.

Product Parameter

ITEM | MODEL | POWER |

01 3-Compartments Batching Station | PL1600 III | 13KW |

02 Belt Conveyor | 8M | 2.2KW |

03 Cement silo | 50T |

|

04 Water Scale | 100KG |

|

05 Cement Scale | 300KG |

|

06 Screw Conveyor | 6.7M | 7.5KW |

07 Enhanced Mixer | JS1000 | 51KW |

08 Dry Mix Conveyor | 8M | 2.2KW |

09 Pallets Conveying System | For QT12-15 System | 1.5KW |

10 QT12-15 Block Machine | QT12-15 System | 54.2KW |

11 Block Conveying System | For QT12-15 System | 1.5KW |

12 Automatic Stacker | For QT12-15 System | 3.7KW |

A Face Mix Section (Optional) | For QT12-15 System |

|

B Block Sweeper System(Optional) | For QT12-15 System |