Cat Large Dozers D9T

Product Feature

MOVE with MORE RESPONSIBILITY

Meeting regulations is very important for your business. The D9T is powered by Cat C18 engine with ACERT Technology – which meet today's most stringent emissions standards and are poised to take on tomorrow's challenges as well. Power through tough materials with full rated net power of 436 horsepower at 1,800 rpm.

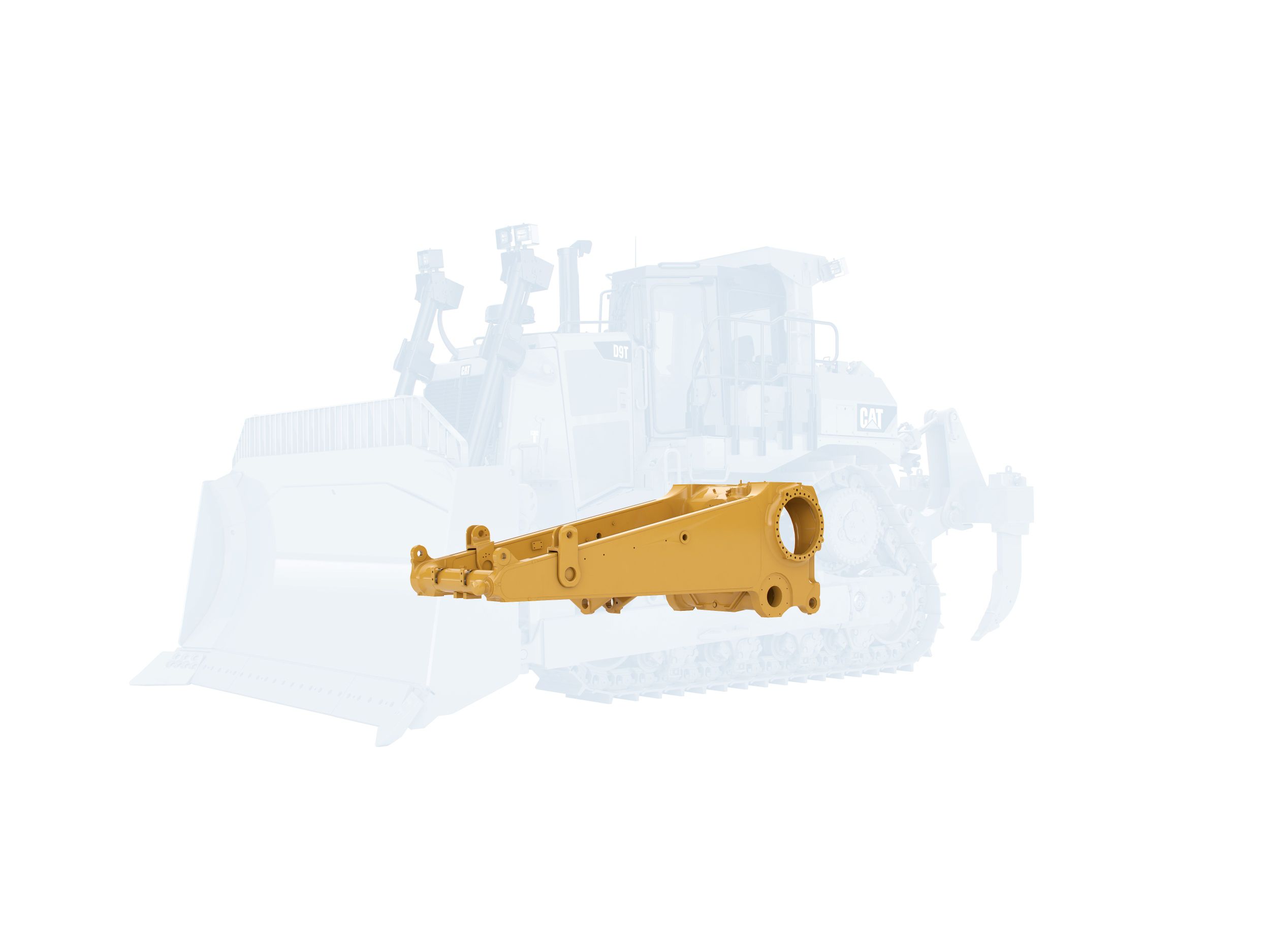

MOVE with MORE RELIABILITY

You can't afford to have operators not dozing. Helping you get more done with maximum availability, the D9T's durable design makes repair and maintenance easy. You can rebuild these dozers several times using the same frame with only minor repairs. It's not unusual for a Cat dozer to log more than 100,000 hours. The backbone of the dozer is a heavy, strong and durable frame with high-strength steel castings and continuously rolled top and bottom frame rails. The D9T frame provides durable support to the undercarriage, elevated final drives and other components.

Modular Design

Mechanical availability is one of your top concerns. The D9T reduces downtime by making our machines easy to repair and maintain. Major components are modular in design, so most can be removed and reinstalled without disturbing other systems – which allows the D9T back on the job faster.

MOVE with MORE CONFIDENCE

You consider the safety of your workers a top priority, and we're doing our best to help you meet your safety goals. Caterpillar considers the safety of everyone in, on or around Cat equipment when developing new products or enhancing safety features for existing products. The D9T has numerous safety features such as but not limited to:

Access / Egress Lighting

Visibility Arrangements

Push-arm Grab Handle, Steps and Guardrails

Anchorage Points

Operator Not Present Monitoring System

MOVE with MORE VERSATILITY

Every day you are focused on productivity and cost per unit for increased profitability. With the D9T fully suspended undercarriage you will get more cycles per day. Every additional cycle you get because of the smooth ride means increased production and lower cost per unit of material moved. The elevated sprocket and suspended undercarriage work together, increasing traction and giving the operator a smoother ride. The elevated sprocket design transfers implement shock loads to the mainframe, so final drives, axles and steering components are isolated from harsh impacts. These benefits translate into higher production and longer component life.

MOVE with MORE EFFICIENCY

Productive operations begin with a productive operator. Noise, stress and fatigue all have an effect on operator performance – so we've designed an environment that helps minimize them. Within the D9T the operator environment is more than a cab; it's an integrated electronic platform designed to maximize productivity. The new Information Display screen is larger, faster and more powerful with increased memory and intuitive menu structure.

MOVE with MORE INTELLIGENCE

You expect advanced solutions for improved uptime and performance. Several electronic features have been integrated into the D9T to help a less skilled operator become better and obtain the most out of the machine to help reduce operator fatigue and get more done at a lower cost per unit of material moved. The D9T has several electronic options including but not limited to:

Automated Blade Assist

Autocarry

Adaptive Load Select

Automatic Ripper Control

Cat Grade Control 3D

Cat MineStar System

Cat MineStar System is an integrated suite of mine operations and mobile equipment management technologies. Customers can configure the optional sets: Fleet, Terrain, Detect, Health and Command – to manage multiple operations and gather real-time feedback to enhance safety, productivity and efficiency.

MOVE with MORE SUPPORT

Your Cat dealer knows how to keep your machines moving. We've built an extensive network of nearly 200 locally owned businesses in over 200 countries. So wherever you operate, there is a dealer nearby to provide world-class service and support for your Cat equipment.

Product Parameter

Overview

The Cat D9T has a reputation for outstanding productivity, operator comfort, and robust reliability. It is a highly versatile machine flexible enough to be used in heavy construction, quarries, landfills, forestry, and mine sites. Cat customers can count on the D9T's continued legacy of superior performance, long life, ease of operation and world-class service from the global Cat dealer network to be the backbone of their operation.

Engine

Units:

| Flywheel Power | 436.0 HP 325.0 kW | More |

| Emissions | U.S. EPA Tier 4 Final and EU Stage IV U.S. EPA Tier 4 Final and EU Stage IV | More |

Engine - U.S. EPA Tier 4 Final/EU Stage IV

| Engine Model (1) | Cat® C18 ACERT™ Cat® C18 ACERT™ | More |

| Net SAE J1349/ISO 9249 | 436.0 HP 325.0 kW | More |

| Bore | 5.7 in 145.0 mm | More |

| Displacement | 1106.0 in³ 18.1 l | More |

| Engine Model (2) | Cat C18 ACERT Cat C18 ACERT | More |

| Engine Power - Gross SAE J1995* | 469.0 HP 350.0 kW | More |

| Engine Power - ISO 14396 | 460.0 HP 343.0 kW | More |

| Engine Power - Net Power SAE J1349/ISO 9249 | 436.0 HP 325.0 kW | More |

| Note | *Excludes all fan losses. *Excludes all fan losses. | More |

| Stroke | 7.2 in 183.0 mm | More |

Weights

| Operating Weight | 106618.0 lb 48361.0 kg | More |

| Shipping Weight | 80062.0 lb 36316.0 kg | More |

Dimensions

| Drawbar Height (Center of Clevis)* | 30.0 in 763.0 mm | More |

| Ground Clearance* | 23.4 in 596.0 mm | More |

| Height - FOPS Cab* | 150.4 in 3820.0 mm | More |

| Height - ROPS/Canopy* | 157.5 in 4000.0 mm | More |

| Height - Top of Stack* | 157.4 in 3997.0 mm | More |

| Length - Basic Tractor - With Drawbar | 204.0 in 5180.0 mm | More |

| Length - Basic Tractor - With Winch | 218.3 in 5545.0 mm | More |

| Length - With Multi-Shank Ripper | 257.4 in 6538.0 mm | More |

| Length - With SU-Blade** | 270.9 in 6880.0 mm | More |

| Length - With Single-Shank Ripper | 257.0 in 6529.0 mm | More |

| Length - With U-Blade | 274.3 in 6967.0 mm | More |

| Overall Length - Basic Tractor | 193.3 in 4910.0 mm | More |

| Overall Length - SU-Blade/SS Ripper | 324.0 in 8230.0 mm | More |

| Track Gauge | 88.6 in 2250.0 mm | More |

| Width - Over Trunnions | 129.9 in 3300.0 mm | More |

| Width - Without Trunnions - Standard Shoe | 113.4 in 2880.0 mm | More |

| Note (1) | *Includes grouser height for total dimensions on hard surfaces. *Includes grouser height for total dimensions on hard surfaces. | More |

| Note (2) | **Includes drawbar. **Includes drawbar. | More |

| Length - Track on Ground | 136.6 in 3470.0 mm | More |

Transmission

| 1 Forward | 2.4 mile/h 3.9 km/h | More |

| 2 Forward | 4.2 mile/h 6.8 km/h | More |

| 3 Forward | 7.3 mile/h 11.7 km/h | More |

| 1 Reverse | 2.9 mile/h 4.7 km/h | More |

| 2 Reverse | 5.2 mile/h 8.4 km/h | More |

| 3 Reverse | 8.9 mile/h 14.3 km/h | More |

| 1 Forward - Drawbar Pull | 161000.0 716500.0 N | More |

| 2 Forward - Drawbar Pull | 90000.0 400500.0 N | More |

| 3 Forward - Drawbar Pull | 50000.0 222500.0 N | More |

Hydraulic Controls

| Pump Type | Piston-type pump geared from flywheel Piston-type pump geared from flywheel | More |

| Pump Output - Steering | 102.0 gal/min 387.0 l/min | More |

| Pump Output - Implement | 60.0 gal/min 226.0 l/min | More |

| Tilt Cylinder Flow - Rod End Flow | 37.0 gal/min 140.0 l/min | More |

| Tilt Cylinder Flow - Head End Flow | 50.0 gal/min 188.0 l/min | More |

| Tilt Cylinder Relief Valve Setting | 2800.0 psi 19300.0 kPa | More |

| Ripper - Lift - Relief Valve Setting | 3800.0 psi 26200.0 kPa | More |

| Ripper - Pitch - Relief Valve Setting | 3800.0 psi 26200.0 kPa | More |

| Tank Capacity | 23.5 gal (US) 89.0 l | More |

| Lift Cylinder Relief Valve Setting | 3800.0 psi 26200.0 kPa | More |

| Steering System - Pressure | 5875.0 psi 40500.0 kPa | More |

Undercarriage

| Shoe Type | Extreme Service Extreme Service | More |

| Width - Shoe | 24.0 in 610.0 mm | More |

| Shoes/Side | 43 43 | More |

| Grouser Height | 3.3 in 84.0 mm | More |

| Pitch | 9.4 in 240.0 mm | More |

| Ground Clearance | 23.5 in 596.0 mm | More |

| Track Gauge | 88.6 in 2250.0 mm | More |

| Length - Track on Ground | 136.6 in 3470.0 mm | More |

| Ground Contact Area | 6569.0 in² 4.24 m² | More |

| Track Rollers/Side | 8 8 | More |

| Number of Carrier Rollers | 1 per side (optional) 1 per side (optional) | More |

Service Refill Capacities

| Fuel Tank | 217.0 gal (US) 821.0 l | More |

| Cooling System | 25.9 gal (US) 98.0 l | More |

| Engine Crankcase* | 9.7 gal (US) 37.0 l | More |

| Power Train | 43.3 gal (US) 164.0 l | More |

| Final Drive - Each | 3.9 gal (US) 15.0 l | More |

| Roller Frames - Each | 11.9 gal (US) 45.0 l | More |

| Pivot Shaft Compartment | 7.9 gal (US) 30.0 l | More |

| DEF Tank | 9.5 gal (US) 36.0 l | More |

| Hydraulic Tank Oil - Only | 23.5 gal (US) 89.0 l | More |

| Note | *With oil filters. *With oil filters. | More |

Winches

| Winch Model | PA 140VS PA 140VS | More |

| Weight* | 3950.0 lb 1790.0 kg | More |

| Oil Capacity | 4.0 gal (US) 15.0 l | More |

| Increased Tractor Length | 21.9 in 557.0 mm | More |

| Drum Width | 12.6 in 320.0 mm | More |

| Note | *Weight shown is base winch only. Does not include mounting arrangement, control arrangement, oil, or wire rope. With counterweight: 3700 kg (8,150 lb). *Weight shown is base winch only. Does not include mounting arrangement, control arrangement, oil, or wire rope. With counterweight: 3700 kg (8,150 lb). | More |

| Maximum Drum Capacity - Optional Cable Length | 204.0 ft 62.0 m | More |

| Maximum Drum Capacity - Recommended Cable Length | 257.0 ft 78.0 m | More |

| Wire Cable Diameter - Optional | 1.25 in 32.0 mm | More |

| Wire Cable Diameter - Recommended | 1.13 in 28.0 mm | More |

| Wire Cable Ferrule Size - Length | 2.8 in 70.0 mm | More |

| Wire Cable Ferrule Size - Outside Diameter | 2.4 in |