Product Feature

● Structure

Main frame strength

D10T2's durable design simplifies service and maintenance,Optimal availability achieved,Enables you to get more done。The customer only needs to make minor repairs.,These tractors can be refurbished multiple times using the same frame。

In demanding dozing and ripping applications,D10TThe main frame can effectively absorb high impact loads and torques。

Main housing、The stabilizer bar saddle and front crossmember are heavy duty steel castings and are integrated into the high load area of the main frame,To improve the stress distribution,Thereby improving the durability。

The top and bottom rails are made of continuous rolled steel,Ensures superior durability of the mainframe。

The main housing keeps the final drive away from the ground working area,To protect it from impact.、Wear and contamination。

The pivot and pin mounted equalizer bar keeps the track roller frame in alignment,And allow that roller frame to oscillate for a smooth ride。

Balance bar end pin

Properly lubricated working surfaces can significantly extend component life,It also helps reduce maintenance costs.。

The accessible service point on the left side fender not only D10T2 Carry out remote lubrication,The operator or service technician can also lubricate the left and right equalizer bar terminal pins and the terminal pin bearings from a single service point。

After the optional automatic lubrication system is added,On the message display, the operator can customize the amount of grease required for each application based on volume and service interval。

● Engine

Adopt ACERT Technical C27

From D10T To D10T2 evolved to maximize productivity and fuel efficiency。Adopt ACERT Technical Cat CThe 27 engine is powerful and very reliable,Able to ensure optimal performance、High productivity and excellent service life。

C27 ACERT When the engine speed reaches 1800 rpm Resulting in 447 kW(600 hp)Full net power of(SAE J1349/ISO 9249),Torque reserve up to 21%(Forward gear),So that D10TAble to shovel hard materials.。

When used in conjunction with an efficient torque divider and an electronically controlled power shift transmission,It can ensure the long-term reliable operation of the machine。

Power management

C27 ACERT The engine is used A4E4 Engine controller,It automatically switches the engine power setting according to the direction of travel,Maximize your material handling capacity with every drop of fuel。

D10T2 can be provided when the machine is in reverse 538 kW(722 hp)Rated net power of(SAE J1349/ISO 9249)。

Power is increased by approximately 20% when the machine is in reverse%,You can return faster,Thus reducing cycle times,The productivity is improved,The handling cost per unit of material is reduced。

Air-to-air aftercooling system

By supplying more cold air,Engine power can be increased、Reduce emissions and improve fuel efficiency。• D10TThe air-to-air aftercooling system on the 2 cools the compressed hot air from the turbocharger,Thereby providing greater density to the intake system、Cooler air。Show more information

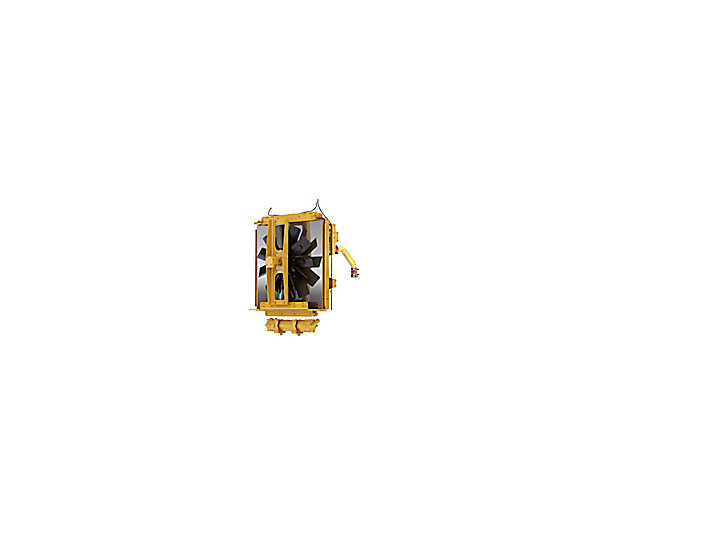

● Cooling system

D10T2 Durable in the worst jobsite conditions、Efficient cooling。

Aluminum thin wall radiator - 6 FPI

The cooling system uses a two-piece radiator,Built-in solid, efficient, thin-walled aluminium movement。Aluminum thin wall construction for durability,The heat transfer is good,Extremely resistant to corrosion。

Hydraulic oil air cooler

Hydraulic oil air coolers extend component life by reducing the temperature of the hydraulic oil,This helps save on repair and maintenance costs.。

Hydraulic variable speed demand fan

By means of a hydraulic variable speed demand fan,Customers are able to increase production、Improve fuel economy、Reduce fan noise and avoid excessive engine cooling。The fan operates according to the ambient condition。In a cooler environment,The fan runs at a slower speed;It consumes only a small amount of power to cool the dozer system,Allow more power to be transferred to the track,Therefore, it helps to reduce the handling cost per unit of material.。

Tooling

Reversible cooling fan

Mesabi Radiator

● Hydraulic system

D10T2 Equipped with field proven load sensing tooling hydraulics,It meets the operating requirements by automatically and continuously adjusting the hydraulic power of the tooling,Thereby improving fuel efficiency and machine performance。Since the hydraulic flow is provided only when the tooling command is issued,Therefore, the tracks get more power to propel the machine forward,The performance of the bulldozer is improved。

D10T2 Load Sensing Hydraulics have been improved with a multi-function interaction mechanism,Enhanced blade control during dozing,So that that material can be efficiently transport。

Synchronized dozer commands from two tooling pumps with newly designed valves(Uch as tilt、Tipping and lifting)And synchronized ripper command(Uch as lifting and tipping)。This improves machine performance and operator efficiency。

D10T2 Unmatched single and double dip breakout force。The machine now has a separate tilt valve section,It is possible to provide the same tilt breakout force on the left and right sides with a dual tilt device。

● Power train

D10T2 Powertrain design optimizes performance and ease of operation,Help customers get more done at the lowest cost per unit。

Advanced Productivity Electronic Control System(APECS)

Advanced Productivity Electronic Control System(APECS,Advanced Productivity Electronic Control System)Yes D10T2 Main factors to improve shift performance and quality。The operator will experience greater comfort when changing gear,Take operator productivity to new level。The most important thing is,APECS Provides premium shift quality that is played by an enhanced automatic shift.(EAS)The main driver of all the benefits。

Enhanced autoshift(EAS)

D10TA standard feature of 2 is that EAS。EAS Automatic selection of the best combination of gear and engine speed depending on the load on the power train and the required ground speed,Thereby improving fuel efficiency and productivity.。This function is similar to an automatic transmission。EAS Function and higher reverse power increase productivity when the machine is backing up on an incline。

Bidirectional shift

This convenient feature helps reduce operator workload during operation。Using the Bidirectional Shift Function,The operator only needs to change the direction,The desired forward and reverse gears or the desired forward and reverse speeds are automatically selected(When EAS When activated)。

Automatic downshift

This feature increases safety and productivity during the dozing cycle,Can create more value for customers。Not in EAS Mode time,The automatic downshift feature automatically downshifts the transmission when a sharp increase in load is detected,But when the load is reduced,This feature does not automatically upshift。The automatic downshift feature allows the operator to achieve maximum performance with minimum effort。The operator can override these autoshift functions at any time。

Torque divider

Single-stage torque converter with output torque divider,It outputs 75 through the torque converter% Engine torque,And that remainder 25 is output via a direct drive shaft.% Engine torque,Better driveline efficiency can be achieved、Higher torque multiplication and easier operation。

Planetary Power Shift Transmission

3-speed forward and 3-speed reverse,Adopt large diameter、High capacity and oil cooled clutch。

The regulation system can be controlled by the Advanced Productivity Electronic Control System(APECS)Enables fast speed and direction changes。

Oil-water type cooler for optimum cooling capacity。

Forced oil flow lubricates and cools the clutch pack,Maximize clutch life。

Even if the ripper is installed,The modular transmission and bevel gear can also be slid into the rear axle housing,And is convenient to maintain。

Steering Clutch and Brake

Anti-attenuation,No adjustment。The multi-disc, oil-cooled steering clutch is hydraulically operated,Electronic control。The spring applies the brake,Hydraulic brake release,Security is achieved、Reliable braking performance。Steering Clutch、The brakes and final drives can be removed from each side of the tractor as a unit.。

● Chassis system

Overhead sprocket and suspended undercarriage work together,The traction force is increased,But also make that operator drive more smoothly.。The elevated sprocket design transmits the vibratory loads applied to the tooling to the main frame,Make the final drive、Axles and steering components are protected from strong impact,These advantages complement each other,Significantly improve productivity,Extend the service life of components。

The bogie suspension allows the track to conform to the ground condition,Can be increased by as much as 15% Ground area of,Pecially on rough, hard ground.。Higher traction means less slip、The balance is higher、The ride is smoother。

The integrated carrier roller mount is cast into the track roller frame,Easy to add optional carrier rollers on site。

To further improve durability where workloads are heaviest,The redesigned roller frame consists of three(3)A main casting,Protection against bending and twisting。Improvements to the roller frame also include a thicker rear main bogie pivot pin、Redesigned carrier roller mounting pad and better main bogie mounting location。

Track master links with single tooth and coarse thread bolt,Can provide excellent reliability and durability。

● Tools and tools

Bulldozer blade

All blades feature a rugged box section design,To prevent twisting and cracking。The blade is made of high tensile strength steel,Easily handle the most demanding tasks。Heavy-duty moldboard construction with hardened bolt-on cutting edges and end bits,Increased strength and durability。

Large capacity U Shovel – Provides maximum capacity,Suitable for transporting large loads over long distances。

SU Type Blade – For harsh applications requiring high penetration。

Double tilt device – Allows the operator to optimize the blade pitch angle。

Cutting edge and end edge – The cutting edge is made of DH-2™ Made of steel。The end blade is made of DH-3™ Made of steel,Maximizes service life when working with tough material。

Cat Work Tools A variety of specialized blades are available,Including the coal shovel、Cushion dozer blade、Reclamation shovel and sawdust shovel。

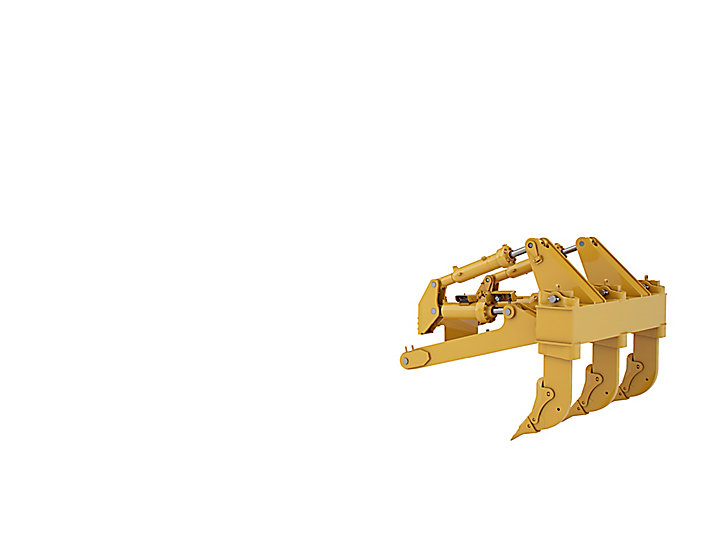

Ripper

The ripper is capable of quickly penetrating and thoroughly splitting a wide variety of hard materials.。

Single Shank Ripper – Built for tough ripping conditions,Can provide better ripping depth。The operator can adjust the ripper shank depth from the seat using an optional single shank pin puller。Wide upper frame viewing port,Helps the operator observe the condition of the ripper tip。

Multiple Shank Ripper – Typically used to handle less rigid materials in light ripping applications。Deliver a high level of productivity。Single toothed bar can be selected for bulldozer according to different materials.、Double or triple shank ripper。

Deep Ripping Shank Bucket Tooth – Optional deep shank ripper teeth are available for single and multiple shank ripper。

CAPSURE™ Non-Impact Ripper Tip and Shank Guard Retaining System

By rotating 180 degrees ¾" Ratchet,Tip and shank protectors can be easily installed。This simple installation means no hammering,Therefore, the safety is improved。It also enables quick replacement,Reduce downtime。

Rear counterweight

The rear counterweight provides the correct balance for the tractor,O as to maximize the productivity of the dozing operation。If not equipped with any other rear tooling,This device is recommended。

● Console

D10TThe cab of the 2 offers user-friendly controls、Intuitive monitoring system and wider vision。D10TAll new features in the 2 operator station create an industry-leading operating environment,Helps to achieve high levels of productivity、Efficiency and comfort。

Comfortable operation

Available on standard machines 77 dB(A)Operator noise level for。If the optional silencing kit is installed,The noise level can be further reduced。

Cat The Optimized Series seats offer six adjustment controls,Ensure optimum support and comfort。Pecially in slope operation,The seat side bolsters prevent the operator from moving from side to side。

The automatic temperature control system automatically adjusts the heating and air conditioning controls.,To keep the cab at a comfortable temperature throughout the day。

Wide panoramic view

To improve safety and productivity,Operator station provides excellent visibility。

Conical bonnet,Recessed fuel tank and narrow ripper frame provide a clear view of the front and rear work area。

Information display

The colour touch-screen display is located at the front of the right-hand console,Through it,Not only can the operator monitor machine performance,Machine parameters can also be easily modified.,O that performance can be tailored to the task at hand。

Information display with larger screen and memory and intuitive menu structures,Run faster,The performance is stronger。

Of the information display“Work monitor”The menu screen displays the performance data of the machine,It also provides real-time feedback based on the machine's performance,To optimize productivity。

Other functions:

Secondary Engine Shutdown Switch

Communication radio mounting

Radio preparation for entertainment and IPOD/MP3 Player preparation

Power socket on the right console(Compatible with 12-volt laptops and wireless phones)

Optional heated and ventilated seats

Optional 5th Percentile Arrangement,Provides ergonomic design for short operators

Optional double-pane impact-resistant glass

Optional Cat 40 psi Super-tempered glass

Tooling and steering control device

Fingertip controls(FTC)Effortless and comfortable,Convenient for operators to work for a long time。The electronic control eliminates a direct mechanical connection to the power train,The noise is reduced,Reduced vibration in the cab。 The low-effort electronic blade control handle allows the operator to control all dozing functions with one hand。 The ripper joystick is located on the right side of the operator,Directly behind the bulldozer joystick。Securely mounted handles provide strong support for the operator,Ripping even on the roughest ground,The same is true。

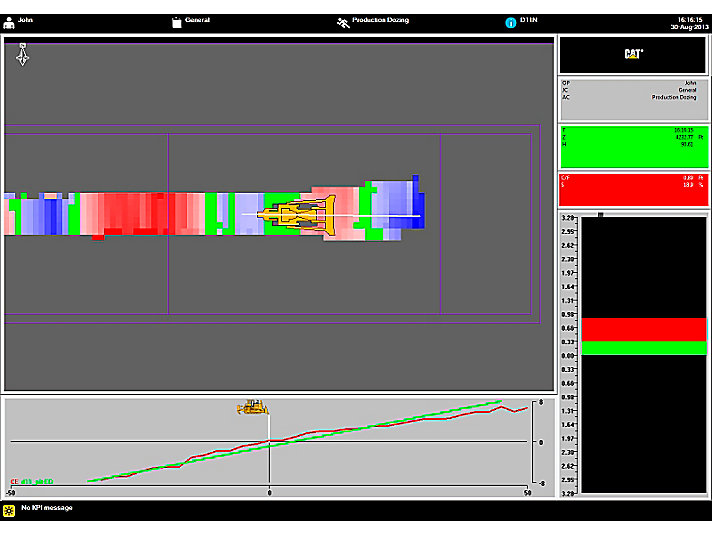

● Integration technology

D10T2 Electronic systems are fully integrated,In order to work as a machine。This integration makes the machine intelligent.,Make the operator more aware of the working condition,Thereby maximizing the productivity of both.。

VIMS™ 3G – The system collects historical trends through a connecting line.、Bar Chart、Events and other information,In order to VIMS PC And other applications for off-board analysis.。

Product Link™/VisionLink® – Product Link Used to remotely transmit information about device location、Operational and health information。It can be effective、Efficiently monitor the performance of your assets,Helps you complete your assignments on schedule,Keep the equipment in the best operating condition,And reduce the owning and operating costs of the equipment fleet。

Blade Auto Assist(ABA,Automated Blade Assist)Function – Improve work efficiency,And that workload of operator is reduced。ABA Use preset blade flat tilt position。When the machine is equipped with the optional dual tilt,ABA Yes D10TStandard configuration of 2。

AutoCarry™(Optional)– Autocarry Use of high performance chassis-mounted global navigation satellite systems(GNSS,Global Navigation Satellite System)Receiver to measure ground speed and track slip,O as to realize the automatic control of the shovel blade in the transportation link of the bulldozing circulation.。The blade position is automatically adjusted to keep the slip at an optimal level,For optimal performance。Autocarry For transport distances exceeding 30.5 m(100 ft)Improves operator productivity in high-capacity earthmoving operations。

Automatic Ripper Control(Optional)– This new feature relieves operator fatigue and reduces machine wear。It utilizes a roll-over protection structure mounted(ROPS)On it GNSS To monitor the speed of the bulldozer.,Automatic adjustment of engine speed and ripper depth,This minimizes track slippage。

● CAT MINESTAR

Cat MineStar Helps you manage everything,Including material tracking、Complex Real-Time Device Cluster Management、Machine Health System、Automatic equipment system, etc.。Performance kit(Fleet、Terrain、Detect、Health And Command)Can be used in combination or separately,To provide the required flexibility and scalability,Make work more efficient and safe。

Fleet(Optional)Provide real-time machine tracking、Job assignment and productivity management,Gives the mine a full view of all operational activities。

Terrain for Grading(Optional)It is an advanced machine guidance system,Provide real-time productivity information to operators of mine leveling equipment。Terrain With in-cab display、Satellite Navigation Technology、Machine-mounted components and fully integrated office software。

– Except for systems that display only terrain,Caterpillar Blade control will also be released(Optional)A new generation of systems。The new Blade Control feature Cat Based on mature software used in other technology products,It can not only automatically guide the blade to move along the ideal design path,,But also with Autocarry Integrated to sense and automatically control the load of the blade,This improves machine performance and blade load efficiency in high energy dozing applications。

Detect(Optional)It can improve the operator's understanding of the surrounding environment of the equipment.,Helps eliminate potential safety hazards and increase operator confidence。

Health(Optional)Be able to provide your entire fleet of devices with important、Event-based machine condition and operating data,Helps the mine identify potential equipment problems early。

Command for Dozing(Optional)Free the operator from the cab of the machine,And that remote control operation is realize。

– Over the shoulder console provides line-of-sight remote control。

– Comfortable remote operator station with line-of-sight and non-line-of-sight remote control。

For more information,Please visit cat.com/mining。

● Safe

Safe is Caterpillar The most important thing。We continuously improve our products and engineering,To help our customers achieve their safety goals and create a safe work environment。

Seat belt warning system

Whenever the machine is started with the key,This function will remind the operator to fasten the seat belt -(LCD Icon)。If the operator still does not fasten the seat belt and puts the machine into gear,There will be a shrill sound.。

Operator Absence Monitoring System

In some cases,This function locks the power train and the hydraulic system,Avoid unexpected movement of the machine when the operator is not in the seat。

Heavy duty treading ladder and handrail

Carefully arranged handlebars and non-slip steps and decks,Help the operator get on and off the vehicle。

Observers are silenced

D10T2 Three options are available to control operator and observer noise levels。Options include:

Bottom seal cover。

Robust engine compartment shell with sound insulation。

Silencing idler and sprocket segment。

After ordering all three option,Compared to a cab without the noise reduction option,D10TThe silencing kit reduces the average noise power level of the observer4 dB(A)(ISO 6395),The average sound pressure level for the operator is reduced by 3 dB(A)(ISO 6396)。

Lighting kit

D10T2 offers a variety of optional lighting kits,Enhances the operator's view of the surrounding environment when working at night。

Halogen lamp

High intensity discharge(HID)Light

Cat Light emitting diode(LED)Work lights

Anchor point

At D10T2 up,Anchors are used to provide a positioning mechanism for workers,In order to perform service and maintenance。D10TThere are fourteen(14)An anchor point。

Lift Cylinder Spray Cover Upper IV(4)A

Four on the top surface of the hood(4)A

Cab front upper two(2)A

ROPS Structurally four(4)A

Fire Suppression System

D10T2 The fire extinguishing system preparation and fire extinguishing system are installed at the factory.。

Two(2)A LVS 38 L(10 gal)Fire extinguisher

16 nozzles,Located under the hood and operator station

Two(2)A manual switch(One [1] One in the cab,The other one [1] One is located in the maintenance center near the ground.)

Integrated control module

Display inside the cab

CAT Electric boarding system(Optional)

Cat The electric boarding system provides perfect access to and from the cab,Even in rainy or freezing weather conditions,The operator can also easily enter and exit the cab。

The powered stairway extends and folds in seconds.。

The guardrails on both sides of the escalator provide three-point contact,Ensure operator safety。

If the parking brake is released or the blade is raised with the ladder down,An alert is issued。

Rear platform and guardrail(Optional)

The platform allows the rear side lamp to be cleaned and serviced from the rear window。The walkway adopts modular design.,Different lengths can be laid along the rear side of the dozer,To meet the specific needs of the customer。

Two-step dozer blade lifting cylinder maintenance platform with guardrail

This platform provides easy access to the lift cylinder,O that the mirrors and lamps can be cleaned or serviced。

● Convenient maintenance

Floor maintenance option

D10T2 A key advantage of modular design,Is the ability to replace old parts with pre-tested remanufactured or refurbished parts.,This allows the machine to be put back into service more quickly。

Floor maintenance option

Ground level service center mounted on ripper cylinder or counterweight,Convenient:

Lighting switch

Engine shutdown switch

Raise and lower the stairway by hydraulic operation

Oil change at high speed

As standard in the engine room,The high speed oil change system not only controls the oil,It also increases the oil change rate for the engine and power train。At D10T2 up,The high speed oil change system can be installed on either the ripper or the counterweight,For access from the ground。

OK to start

“OK to start”The strategy can adjust the engine coolant when the machine is started.、Electronic Level Verification for Engine Oil and Power Train Oil System。All information is available through the information display in the cab。

Fast refueling system

Fast refueling system installed close to the ground,And is convenient to operate,But also has an active cut-off function for preventing fuel spillage.,Reduces fuel waste and downtime。

● Customer support

It has a long reputation CAT Dealer support

From helping you choose the right machine to providing ongoing technical support,Cat Dealers can provide unparalleled sales and support services。

Preventative maintenance program and warranty contract。

First-class parts supply。

Provide training for operators,Help you improve your economic efficiency。

Cat Original Remanufactured Parts。

● Sustainability

For Caterpillar In terms of,Sustainable development is the use of technology and innovation,Higher efficiency and productivity with less environmental impact,And help you achieve the same goal.(By providing products that use resources efficiently、Services and solutions to increase your business productivity)。Newly launched D10T2 has many sustainability benefits:

Engine is more fuel efficient:

– Adopt C27 ACERT Of the engine D10T2 is able to reach the equivalent of Tier 2 and Stage II Emission level of emission standard,With execution of the same compound duty cyclic D10T Compare,Up to 10% more fuel efficient%。

Lower operator and observer noise levels reduce disturbance of machine operations to surrounding communities。New type D10T2 Silencing kit is optional,In case of soundproof cab,The operator noise level can be reduced to 74 dB(A)(ISO 6396),Observer noise level down to 111. dB(A)(ISO 6395)。

The optional automatic lubrication system eliminates much of the manual labor required for daily point-by-point manual lubrication,Helps reduce maintenance costs,It also provides the specific amount of grease required for each bearing or lubrication point,Thus reducing the consumption of grease.。

Cat The main components of the bulldozer can be refurbished.。Through Cat Certified Rebuild Plan,The machine can be refurbished twice or even three times.,It is economical and practical,But also save natural resources.。

Product Parameter

| Engine | |

| Engine model | Cat® C27 ACERT™ |

| Flywheel power | 447.0 kW |

| Cylinder bore | 137.0 mm |

| Stroke | 152.0 mm |

| Displacement | 27.0 l |

| Notice (1) | *Exclude all fan losses。 |

| Notice (2) | The engine is rated at 1800 rpm Measured when。 |

| Notice (3) | Nominal net power means that the engine is equipped with an air cleaner、Silencer、Alternator、Power measured at the flywheel for the fan and necessary emission control。 |

| Engine power - ISO 14396(Forward gear/Reverse gear) | 462/562 kW(620/754 hp) |

| Engine power - Net power - SAE J1349/ISO 9249(Forward gear/Reverse gear) | 447/538 kW(600/722 hp) |

| Engine power – Total power – SAE J1995*(Forward gear/Reverse gear) | 470/571 kW(630/766 hp) |

| Net power SAE J1349/ISO 9249(Forward gear/Reverse gear) | 447/538 kW(600/722 hp) |

| Discharge | Tier 2/European Union Stage II Equivalent emission standards |

| Notice (4) | Elevation below 4572 m(15000')Its rated power can be maintained at(Forward gear)。 |

| Weight | |

| Operating weight | 70171.0 kg |

| Shipping weight | 49793.0 kg |

| Gearbox | |

| First gear forward | 4.0 km/h |

| Second gear forward | 7.2 km/h |

| Third gear forward | 12.7 km/h |

| Reverse first gear | 5.2 km/h |

| Reverse second gear | 9.0 km/h |

| Reverse third gear | 15.8 km/h |

| Type | 3-Speed Planetary Power Shift Transmission |

| Transmission clutch diameter | 434.3 mm |

Hydraulic control unit |

|

| Pump type | Variable displacement piston |

| Dozer blade safety valve settings | 28000.0 kPa |

| Tilt Cylinder Relief Valve Settings | 20300.0 kPa |

| Ripper(Promote)Relief valve settings | 28000.0 kPa |

| Ripper(Cutting angle)Relief valve settings | 28000.0 kPa |

| Total pump displacement(Tooling) | 380.0 l/min |

Chassis system |

|

| Type of track shoe | Extreme operation(ES) |

| Shoe width | 610.0 mm |

| Number of track shoes per side | 44 |

| Grouser height | 93.0 mm |

| Pitch | 260.0 mm |

| Ground clearance | 725.0 mm |

| Ground contact area | 4.74 m² |

| Number of track rollers per side | 8 |

| Number of carrier rollers | 1 per side(Optional) |

Maintenance refill capacity |

|

| Fuel tank | 1190.0 l |

| Cooling system | 180.0 l |

| Engine crankcase* | 68.0 l |

| Power train | 230.0 l |

| Final drive(Each) | 23.0 l |

| Roller frame(Each) | 64.0 l |

| Pivot chamber | 33.0 l |

| Notice | *With oil filter。 |

| Hydraulic oil tank | 131.0 l |

Track roller frame |

|

| Swing | 351.0 mm |

Steering and braking system |

|

| Hydraulically actuated multiple disc steering clutch | 392.0 mm |

| Spring-driven multiple disc brake | 392.0 mm |

Standard |

|

| FOPS | Anti-falling object protective structures(FOPS)Meets the following criteria:ISO 3449:2005 LEVEL II。 |

| ROPS | Roll-over protection structures(ROPS)Meets the following criteria:ISO 3471:2008。 |

| Noise (1) | Exterior sound pressure level for standard machine(ISO 6395)115 dB(A)/111 dB(A)(Noise reduction)。 |

| Noise (2) | Operator equivalent sound pressure level(ISO 6396)77 dB(A)/74 dB(A)(Noise reduction)。 |

Size(Approximation) |

|

| Ground contact length of track | 3880.0 mm |

| Track gauge | 2550.0 mm |

| Excluding the width of the trunnion(610 mm/24" ES) | 3292.0 mm |

| Overall Length of Basic Dozer | 5324.0 mm |

| Width(Outside of the trunnion) | 3736.0 mm |

| Basic Dozer Length with Drawbar | 5598.0 mm |

| Drawbar height(To U Clamp center) | 864.0 mm |

| Ground clearance* | 725.0 mm |

| Assembly SU Total length of the blade and single shank ripper | 9158.0 mm |

| Assembly SU Shovel length | 7416.0 mm |

| Assembly U Shovel length | 7750.0 mm |

| Length for Single Shank Ripper Assembly | 7081.0 mm |

| Length when assembling a multi-shank ripper | 7241.0 mm |

| Height(FOPS Cab)* | 4098.0 mm |

| Height(ROPS/Roof)* | 4406.0 mm |

| Height(Top of the exhaust pipe)* | 4356.0 mm |