CAT 834 K Buckets for coal and wood chips Wheel dozer

Product Feature

● Move more material with less fuel

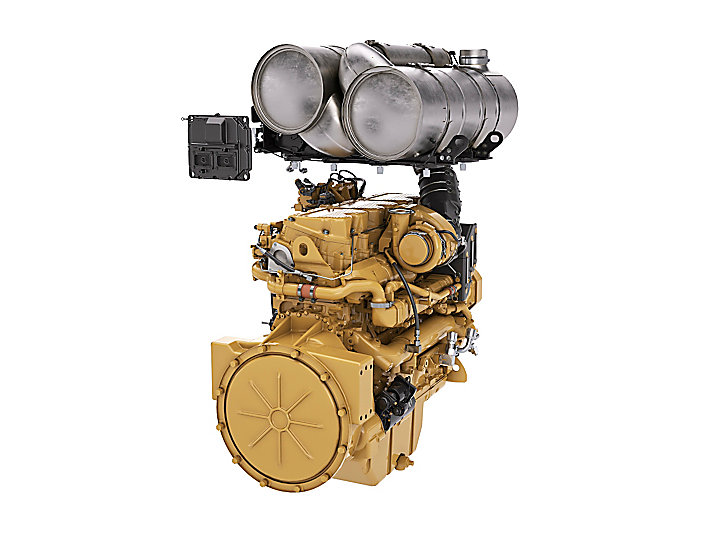

CAT C18 Engine

Cat C18 Engines go through a rigorous manufacturing and testing proces,Ensure your most demanding applications are met。The machine offers three types of C18 Engine options:Compliance with aftertreatment device Tier 4 Final/Stage IV Emission standard engine、Conform Tier 3 engines with equivalent emission standards and meeting Tier 2 Equivalent emission standard engine。

The fully integrated engine electronic control system works with the entire machine,Get more done with your fuel。

Using the Engine Idle Shutdown Function,Reduce fuel consumption at idle speed。

Using the Delayed Engine Shutdown Function,Maximize durability。

CAT Planetary Power Shift Transmission

New Advanced Productivity Electronic Control Strategy(APECS)Transmission control provides more power up hill,And can smoothly shift gears to save fuel。

Pump wheel clutch torque converter(ICTC)

This allows the operator to vary the rimpull of the machine while delivering more power to the hydraulic system,Thereby maximizing efficiency.。

Reduce tire wear

Full throttle shift is possible,Shorten the cycle time

Achieve smooth unloading,The overflow is reduced,And the cycle time is shortened.。

With lock-up clutch CAT Torque converter

Avoid failure of the torque converter,While reducing system heat

Travel at a higher speed

Reduce cycle time for loading and carrying operations。

Higher hydraulic system efficiency

New flow sharing implements and steering load sensing variable displacement piston pump。

Hydraulic flow can now be controlled on demand,Achieve higher fuel efficiency。

Show less information

● Long-term value and durability

Solid construction

Highly durable construction not only enables multiple life cycles,It can also handle the most severe operating conditions.,And ultimately increase your economic benefits.。

The full box section rear frame can withstand strong torsional impact force and twisting force.。

Heavy-duty steering cylinder mounts efficiently transfer steering loads to the frame。

Optimized installation of axles,To enhance structural integrity。

Enlarged lower connecting pin、Dimensions of frame plates and bearings,Prolonged service life。

Rugged construction design

The push beam does more than connect the sides of the rack,But span that entire width of the rack。

When dozing at a corner,The stress is transferred and absorbed by the larger portion of the frame。

● Excellent performance

Steering and Transmission Integrated Control System(STIC™)

Steering and Transmission Integrated Control System(STIC,Steering and Transmission Integrated Control)The system selects the direction、Gear selection and steering operation integrated into a single lever,For optimum response and handling。

A simple sideshift action turns the machine to the right or left.,Thus minimizing operator movement。

Gear selection can be controlled by finger,The operation is very simple。

By using a labour-saving integrated control device,Operation cycle is more stable、Fast,At the same time, the operator's fatigue is reduced.。

CAT Planetary Power Shift Transmission

Best-in-class gearboxes designed for mining operations are your first step to success。

The integrated electronic control incorporates an advanced productivity electronic control strategy(APECS),Uniformity can be achieved、Smooth shifting and greater efficiency。

Heat-treated gears and metallurgical techniques can extend service life and improve reliability。

Four forward speeds and three reverse speeds to meet your application needs。

CAT C18 Engine

834K The machine's second-to-none durability and efficiency comes from Cat C18 Engine。It features a six-cylinder, four-stroke design.,Achieve optimal performance。

Use the electronic control module to optimize performance,Achieve rapid response of engine。

Using mechanically actuated electronic unit injection(MEUI™)System injection timing、Full control of injection duration and pressure,Reliable and efficient。

By reducing the rated speed,The service life of the engine is prolonged.,Improved fuel efficiency。

Emissions options:Tier 4 Final/Stage IV Emission standards、Tier 3 Equivalent emission standards or Tier 2 Equivalent Emission Standard。

Pump wheel clutch torque converter(ICTC)And rimpull control system(RCS)

Adopt advanced ICTC And RCS Obtain modulated rimpull,Thus reducing your operating costs。

When the left pedal is depressed,The rimpull can be increased from 100% Adjust to 25%,Thus reducing tire slip and wear。At 25% After rimpull,The left pedal applies the brake。

RCS The possibility of wheel slip is reduced without reducing the efficiency of the hydraulic system。

Provides direct drive with our lock-up clutch torque converter,Can improve fuel efficiency in some application。

● Comfortable working

Console

Our thoughtful cab features provide operator comfort,Work efficiently。

Cab access

Take advantage of these newly designed ergonomic features,It can be easy、Safe access to the cab。

Folding type STIC Steering device/Armrest。

Smaller boarding ladder angle。

Standard stairway lighting。

CAT Comfort series III Chair

Cat Comfort series III Seat enhances operator comfort,The degree of fatigue is reduced。

Center backrest design and extra thick contoured seat cushion。

Air suspension system。

Levers and controls for the seat are within easy reach,Adjustable in six directions。

Seat-mounted implement control box and move with seat STIC Steering device。

76 mm(3")Wide retractable seat belt。

Control Panel

Switch and message display ergonomically positioned,Keep the operator comfortable at all times。

A large-size backlight membrane switch is provided with LED Activate the indicator lamp。

The switch has ISO Symbol,Convenient and quick identification function。

Two-position rocker switch activates the electro-hydraulic parking brake。

Environment

We clean、Comfortable cab environment increases operator productivity。

Isolated cab mount and air suspension seat reduce vibration。

The automatic temperature control device keeps the cab at a suitable temperature.。

Pressurize the cab with filtered air。

When equipped with sound insulation kit,Noise levels drop to a quiet 71 dB(A)。

Convenient floor-standing tray/Lunch box。

● IntegrationCATTechnology

Technical solutions

834K The electronic system is fully integrated,In order to work as a machine。This integration makes the machine more intelligent.,And give the operator a more complete view of machine operation,Thereby maximizing the productivity of both.。

CAT PRODUCT LINK™

Cat Product Link The system can realize the remote monitoring of equipment.,So as to improve the overall management efficiency of the fleet.。Events and Diagnostic Codes and Service Hour、Fuel oil、Idle time and other details are transmitted to a Web Secure applications for VisionLink™。VisionLink Includes a variety of powerful tools for communicating information to users and dealers,Including graphic analysis、Operating and idle times、Fuel level, etc。

VIMS™ 3G

We have been through the third generation of important information management system.(VIMS 3G)Strive to help customers and operators achieve peak performance。

Easy-to-view graphical information display with large touch screen interface。

Improved user interface for intuitive operation,Navigation is simple。

Reduce service time by letting the operator know of machine system problems or operation。

● Superior technology to get the job done efficiently

Cat MineStar System The most comprehensive system in the industry,It integrates mine operation technology and mobile device management technology.,Flexible configuration according to specific operation requirements。Its functional group - Fleet、Terrain、Detect、Health And Command - Contains a range of technologies,Make it easy for you to handle everything:From fleet assignment and status monitoring,To remote and autonomous control。834K Some of these advanced technologies are used.,Some have become standard factory configuration。

CAT FLEET

Fleet(The motorcade)Kits provide full real-time machine tracking、Vehicle allocation and productivity management,Gives you a comprehensive view of all jobs around the world。

TERRAIN FOR LOADING

834K Equipped Terrain(Terrain)The kit manages loading operations with high precision through the use of guidance technology。It's up 834.K Productivity,And provide you with real-time feedback to improve efficiency。

DETECT

Detect(Detect)The system helps increase operator safety awareness,Thereby improving operational safety.。It includes a range of features.,Designed to assist the operator in observing restricted areas around fixed and mobile equipment。

HEALTH(Health status)

Health The kit displays critical machine status information by event,And display the operation data of the whole fleet.。It has complete equipment health and asset monitoring capabilities,And contains a series of diagnostic、Analysis and reporting tools。

● Safety first

We are constantly introducing new features to our machines.,Make every effort to ensure the safety of operators。

Machine access

45 degree boarding stairs on left and right sides enhance operator access 834K Security of。

In the maintenance area, there is a straight-through walkway with a non-slip surface.。

The maintenance area can be reached from the ground or from a platform,Always maintain three points of contact。

View

Optional heated mirrors ensure greater visibility,In order to achieve safe operation。

Standard Cat Vision(Video)System or option with radar Cat Detect(Detect)The system enhances the operator's knowledge of the environment around the machine。

LED Lights provide excellent visibility into the work space。

Optional on cab LED Warning beacon light。

Operator environment

Isolated cab mount,And seat-mounted implement and steering control,Reduces vibrations transmitted to the operator。

Low internal noise level。

Pressurize the cab with filtered air。

The operator seat is equipped with a standard 76 mm(3")Seat belts。

● Reduce the impact on the environment

834K Sustainability in design and manufacturing。

Engine idle shutdown and automatic idle downshift avoid unnecessary idling,Helps save fuel。

Use of maintenance-free battery,Reduce waste generation。

834K Built for multiple lifecycles。To maximize the service life of the machine,Caterpillar Many sustainability options available,Such as remanufacturing and Certified Rebuild(Certified Refurbishment)Plan。In these plans,40% savings on reused or remanufactured component% To 70% The cost of,Thereby reducing operating costs.。

Caterpillar Complete renovation available,Bring new features to old machine,Maximize your resources。In addition,When you implement Cat When the renovation plan is certified,These refurbishment kits are part of the refurbishment process。

● Achieve higher productivity

Special front connecting rod

Cat Wood Chip Buckets and Coal Buckets have unique capabilities,Able to load by dozing and per trip,Maximize your productivity。This tool is used in conjunction with a specially optimised hydraulic system,Maximizes machine productivity and efficiency。Dual lift cylinders provide hydraulic lift capacity matched to the needs of the application。

Oscillating rear axle

The fixed front axle and the oscillating rear axle ensure that the four wheels are in contact with the ground,Optimum traction and stability。The front axle is securely mounted to the front loader frame,The rear axle can swing。When the rear axle swings,This configuration keeps the operator's line of sight on the bucket,Allows the operator to stay in a smooth and well-sloped work zone on any road condition。

● And that fuel cost is save

834K The following features of the enable better fuel efficiency:

Positive flow control hydraulic system — Provides only the hydraulic flow required for the implement and steering system,Improved fuel efficiency and rimpull。

Engine – Advanced engine controls for optimum power and efficiency。

Engine idle shutdown – Automatic engine and electrical system shutdown reduces fuel consumption。

Lock-up torque converter – Delivers more traction and optimizes fuel efficiency in all applications。

Advanced Productivity Electronic Control Strategy(APECS)– Brand new APECS Transmission control provides more power up hill,And can smoothly shift gears to save fuel。

Configuration of the machine、Fuel consumption is influenced by the skill of the operator and the layout of the job sit。

Machine configuration – Select the correct tooling and tire type for the machine application。Make sure the tires are inflated to the proper pressure。

Idle speed – Set the parking brake,To enable the engine idle speed management system。

● Save on repair and maintenance costs

834K Many design features designed to reduce downtime,Help you succeed。

Ground or platform access and centralized maintenance points facilitate safe maintenance。

Swing-out doors on both sides of the engine compartment make it easy to perform important daily service check。

Ecological outfall helps simplify maintenance,And prevent potential environmental contaminants from escaping。

With the help of important information management system(VIMS,Vital Information Management System)Notice of,Operators and service technicians can fix any problems before they occur,This reduces downtime。

The transmission control valve can be accessed from ground level。

● Top service and support

It has a long reputation CAT Dealer support

Cat The agent is your right partner.,Ready to meet your needs。

Preventative maintenance program and warranty contract。

First-class parts supply。

Improve your efficiency by training your operators。

Cat Original remanufactured parts。

Product Parameter

ENGINE |

|

Engine model |

Cat® C18 |

Cylinder bore |

145 mm |

Stroke |

183 mm |

Displacement |

18.1 l |

Discharge |

America EPA Tier 4 Final/European Union |

Engine |

|

Net power |

370 kW |

Rated speed |

1,900 rpm |

Torque reserve |

52% |

Net power - SAE J1349 |

370 kW |

Peak power speed |

1,500 rpm |

Peak Torque - 1300 rpm |

2836 N·m |

Total power - SAE J1349 |

419 kW |

Gearbox |

|

Direct drive - Third gear reverse |

23 km/h |

Forward - Third gear |

20.3 km/h |

Direct drive - First gear reverse |

7.2 km/h |

Forward - Second gear |

11.6 km/h |

Direct drive - Second gear forward |

12.4 km/h |

Forward - 1st gear |

6.8 km/h |

Direct drive - Second gear reverse |

13 km/h |

Back off - Second gear |

12.2 km/h |

Direct drive - Third gear forward |

22.1 km/h |

Back off - 1st gear |

6.8 km/h |

Back off - Third gear |

21.4 km/h |

Forward - Fourth gear |

35.4 km/h |

Direct drive - First gear forward |

Lockout is disabled |

Direct drive - Fourth gear forward |

38.5 km/h |

Type of transmission |

Cat Planetary power shift |

Remark |

Travel speed is based on |

Brake |

|

Brake |

ISO 3450:2011 |

Axle |

|

Front |

Fixed |

Rear |

Trunnion |

Swing angle |

±13° |

WEIGHTS |

|

Operating weight |

51290 kg |

SERVICE REFILL CAPACITIES |

|

Cooling system |

120 l |

Fuel tank |

793 l |

Maintenance refill capacity |

|

Crankcase |

60 l |

Gearbox |

120 l |

Hydraulic system - Fuel tank only |

140 l |

Differential - Final drive - Rear |

186 l |

Differential - Final drive - Front |

186 l |

Hydraulic system factory filling |

240 l |

Diesel engine tail gas treatment liquid tank* |

33 l |

Note(1) |

All use non-road Tier 4 Final/Stage IV The technology of diesel engines must be Must be used– The sulfur content is equal to or less than 15 ppm(mg/kg) Ultra low sulfur diesel (ULSD)Fuel。 Cat ECF-3、API CJ-4 and ACEA E9Oil to specification。 |

Comment(2) |

*Applies only to the use of Tier 4 Final/Stage IV Machine for emission reduction technology。 |

Working technical specifications |

|

Coal bucket operating weight |

51103 kg |

Sawdust Bucket Operating Weight |

51290 kg |

Noise performance - TIER 4 FINAL/STAGE IV |

Sound insulation |

Operator noise level(ISO 6396) |

72 dB(A) |

Machine noise level(ISO 6395) |

109 dB(A) |

Comment(1) |

According to ISO 6396:Test procedures and conditions specified in 2008, Measure the operator sound pressure level。 – Measured at maximum engine cooling fan speed High speed 70% Under the condition of。 |

Comment(2) |

If the cab is not properly maintained,Or the length of the doors and windows Time is on,Or in In a noisy environment,When operating the machine, Hearing protection may be required。 |

Comment(3) |

According to ISO 6395:Test procedure as specified in 2008 And conditions,Measure the machine sound power level 。– Measured at engine cooling fan speed of To 70% of the maximum speed% Under the condition of。 |

Noise performance - TIER 4 FINAL/STAGE IV - Standard |

|

Operator noise level(ISO 6396) |

73 dB(A) |

Machine noise level(ISO 6395) |

111 dB(A) |

Comment(2) |

If the cab is not properly maintained,Or doors and windows for a long time. Is in the open state,Or in In a noisy environment,When operating the machine, Hearing protection may be required。 |

Comment(1) |

According to ISO 6396:Test procedures and conditions specified in 2008, Measure the operator sound pressure level。 – Measured at engine cooling fan speed of 70% of the maximum speed% Under the condition of。 |

Comment(3) |

According to ISO 6395:Test procedures and conditions specified in 2008, Measure the machine sound power level。 – Measured at engine cooling fan speed of 70% of the maximum speed% Under the condition of。 |

Size(Approximate value) |

|

Height - Top of the exhaust pipe |

4498 mm |

Centerline of front axle to hitch |

2275 mm |

Length - When the sawdust bucket is on the ground |

11974 mm |

Ground to centre of front axle |

978 mm |

Length - When the coal bucket is on the ground |

11971 mm |

Height of top of cab |

4184 mm |

Length - Front end of tire |

8715 mm |

Centerline of rear axle to bumper edge |

3187 mm |

Height - Top of the air cleaner |

3895 mm |

Height - Top of the hood |

3334 mm |

Ground clearance |

531 mm |

Wheelbase |

4550 mm |

Height - Dump the edge of the bucket |

1520 mm |

Height - Retract the edge of the bucket |

2250 mm |

Dump angle at maximum lift height |

64 degrees |

Bucket |

|

Coal bucket handling capacity |

22.9 m³ |

Type |

Large capacity buckets for wood chips and coal applications。Integrated into the bucket The rear mesh screen maintains visibility to the cutting edge。 Due to the larger capacity,So the sawdust bucket model Additional screen on top。 |

Component |

Dual lift cylinders are attached to both bucket,Greater lifting capacity。 The integrated stabilizer system ensures that the bucket remains stable and stable on the machine. Medium layout。The bucket tilt function is standard,It provides ±15 degrees The tilt of,To maintain grade conditions and ensure safe operation。 |

Coal Bucket Dozing Capacity |

45.9 m³ |

Chip Bucket Handling Capacity |

26.8 m³ |

Chip Bucket Dozing Capacity |

53.5 m³ |

Hydraulic system - Promote/Unload/Tilt |

|

Pilot maximum flow |

52 l/min |

Pilot relief valve setting |

4000 kPa |

1900 rpm Maximum flow at speed |

582 l/min |

Promote/Tilt system |

Variable displacement piston |

Double acting cylinder - Left and right Side unloading、Bore and stroke |

127 mm × 838 mm(5.0" × 33.0") |

Promote/Tilt system - Loop |

Belt EH The forerunner of LS Valve |

Relief valve setting - Promote/Tilt |

29000 kPa |

Double acting cylinder - Promote、Bore and stroke |

170 mm × 1107 mm(6.7" × 43.6") |

Pilot system |

Variable displacement piston |

Double acting cylinder - Tilt、Bore and stroke |

152.4 mm × 953 mm(6.0" × 37.5") |

Hydraulic system - Turn |

|

Maximum flow |

250 l/min |

Total steering angle |

86° |

Steering cycle time - Low idle |

5.7 s |

Steering cycle time - High idle |

3.1 s |

Relief valve setting - Turn |

24100 kPa |

Steering system - Pump |

Variable displacement piston |

Steering system - Loop |

Forerunner,Load sensing |

Noise performance - TIER 2 etc Efficiency Standard/STAGE II |

Standard |

Comment(1) |

According to ISO 6396:Test procedures and conditions specified in 2008, Measure the operator sound pressure level。 – Measured at engine cooling fan speed of To 70% of the maximum speed% Under the condition of。 |

Machine noise level(ISO 6395) |

112 dB(A) |

Operator noise level(ISO 6396) |

81 dB(A) |

Comment(3) |

According to ISO 6395:Test procedures and conditions specified in 2008, Measure the machine sound power level。– The measurement is At maximum engine cooling fan speed High speed 70% Under the condition of。 |

Comment(2) |

If the cab is not properly maintained, Or the doors and windows are open for a long time., Or in a noisy environment,When operating the machine, Hearing protection may be required。 |

Noise performance - TIER 2 Equivalent standard/STAGE II |

Sound insulation |

Comment(1) |

According to ISO 6396:As specified in 2008 Test procedures and conditions for, Measure the operator sound pressure level。 – Measured at engine cooling fan speed of To 70% of the maximum speed% Under the condition of。 |

|

|

Comment(2) |

If the cab is not properly maintained, Or the doors and windows are open for a long time., Or in a noisy environment,It is in operation When the machine,Hearing protection may be required。 |

Machine noise level(ISO 6395) |

109 dB(A) |

Operator noise level(ISO 6396) |

81 dB(A) |

Comment(3) |

According to ISO 6395:Test procedures and conditions specified in 2008, Measure the machine sound power level。 – Measured at maximum engine cooling fan speed High speed 70% Under the condition of。 |

Air conditioning system |

|

Air conditioner |

The air conditioning system of this machine uses greenhouse gas refrigerant containing fluorine. R134a (Global warming potential = 1430)。 The system contains 1.8 kg The refrigerant, Its carbon dioxide equivalent is 2..574 metric tons。 |