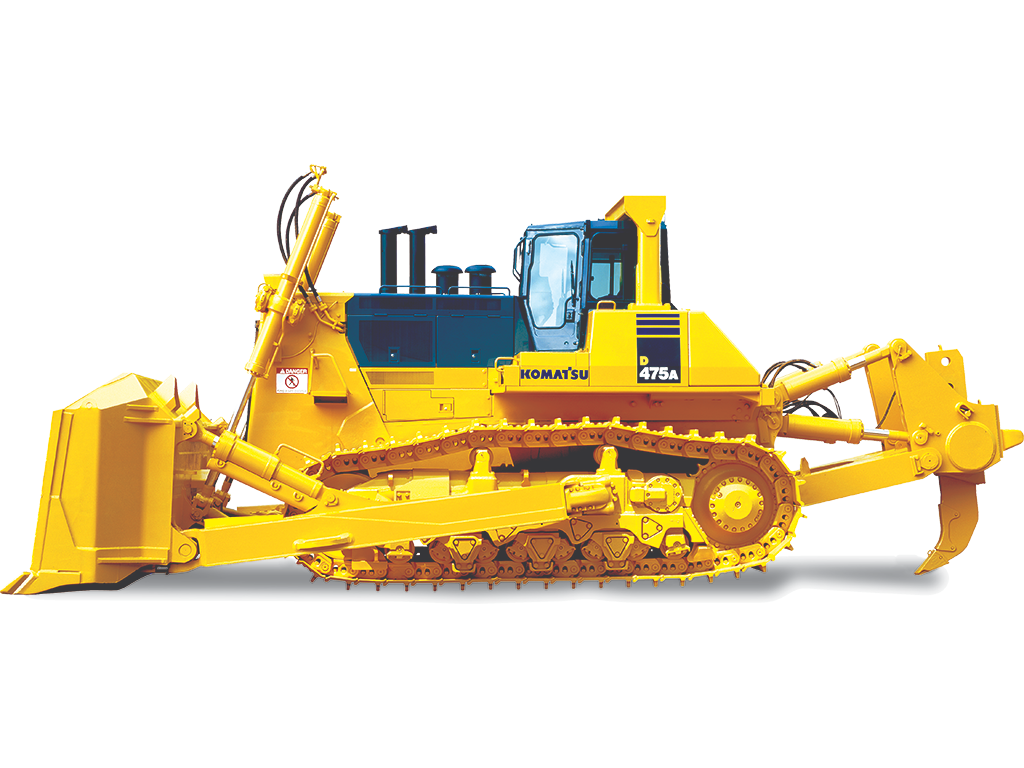

Komatsu D475A-5 LARGE DOZERS

Product Feature

Automatic Torque Converter Lockup System

For greater efficiency during long pushes, the lockup mode allows the system to automatically engage the torque converter lockup clutch. Locking up the torque converter transmits all the engine power directly to the transmission, increasing ground speed and thus achieving efficiencies equal to a direct drive. The results of this efficient use of engine power are less fuel consumption and faster cycle times.

Effect of ECMV Steering Clutches/Brake Control

When dozing downhill, ECMV automatically controls steering clutches and brakes depending on incline of machine or degree of load, reducing counter-steering and producing smooth dozing operation.

When dozing and turning, ECMV automatically controls stroke ratio of steering clutches and brakes depending on degree of load, enabling smooth dozing and turning.

Electronic Controlled Modulation Valve (ECMV)

Transmission

The controller automatically adjusts each clutch engagement depending on travel conditions such as gear speed, RPM and shifting pattern. This provides shockless and smooth clutch engagement, improved component reliability, extended component life, and operator ride comfort.

Steering Clutches/Brakes

Sensors monitor machine operating conditions and electronically control the steering clutches and brakes. Monitoring application parameters such as incline angle of slope and degree of load provides smooth and easy operation by reducing counter-steering on downhill travel, etc.

Fully Adjustable Air Suspension Seat and Travel Control Console

For improved rear visibility during the return portion of the cycle, the operator can adjust the seat 15° to the right. The transmission and steering controls move with the seat for optimum operator comfort. The travel control console is adjustable fore, aft, and for height. The armrest is independently adjustable up and down, providing optimum operation posture for all operators. The operator seat is also tiltable for facilitating downhill dozing.

K-Bogie Undercarriage System

K-Bogies with front and rear single bogies are utilized to increase the length of track on ground improving machine stability and leveling performance. An oscillating idler and increased sprocket lead angle improve riding comfort when traveling over rough terrain. K-Bogies oscillate with two fulcrums assuring a large amount of track roller vertical travel. Impact load to undercarriage components is minimized and durability of components is improved since track rollers are always in contact with track links. Track rollers follow track link movement to extend the undercarriage life. Excellent riding comfort is provided due to less vibration and shock when traveling over rough terrain.

Low Sound Levels

The D475A-5 features a unique and unrivaled low noise design. This is accomplished by improvements not only in the cab but throughout the machine. The cab features an insulated double floor to reduce power train noise, thicker glass in the door and increased pressurization from improved window seals. Engineered baffles on the machine absorb and reduce the fan noise. Cool air inlet ducts are lined with sound absorbing material that direct the air to the hydraulic fan and a double insulated engine hood with additional sound absorbing material further reduce engine noise. These improvements help the D475A-5 achieve remarkably low sound levels.

• Operator noise: 70dB(A) (Engine at high idle, fan speed at 70%, and air conditioner OFF)

• Dynamic noise (outside): 110dB(A) (As per ISO 6395)

Monitor with Self-Diagnostic Function

If the monitor finds abnormalities, a corresponding warning lamp blinks and a warning buzzer sounds to help prevent the development of serious problems. When abnormalities occur during operation, a service user code is displayed.

Palm Command Electronic Controlled Travel Control Joystick

Ergonomically designed palm command travel joystick provides the operator with a relaxed posture and superb control improving operator comfort. Transmission gear shifting is simply carried out with thumb push buttons.

Palm Command PPC Controlled Blade Control Joystick

The blade control joystick uses the Proportional Pressure Control (PPC) valve and joystick, similar to the travel control joystick. PPC control combined with the highly reliable Komatsu hydraulic system enables superb control. Dual tilt and pitch operation are enabled by pressing a switch with the thumb.

Track Link With Wedge Ring

New D375A-6 track links feature reduced press-fit force and a wedge ring. Conventional track pins are retained only with a large press-fit force. (The new track link divides pin forces between the wedge ring and press-fit force.) This enables easier service with reduced pin damage when turning pins and bushings. The result is improved undercarriage life and reduced maintenance cost through reduced wear, greater pin reusability, and reduced maintenance man-hours.

Track Shoe Slip Control Mode

Eliminates the need for the operator to constantly control engine power output with the decelerator pedal while ripping substantially reducing operator fatigue. Maneuverability is improved because the operator is free to focus on the ripping application without having to monitor the track shoe slippage. Repair costs are significantly lowered and undercarriage life is extended with the reduction in track shoe slippage. The track shoe slip control system will contribute to lower fuel costs because the engine output is automatically controlled to optimum levels for operation.

Specifications

Engine

| Model | Komatsu SAA12V140E-3 | |

| Type | 4-cycle, water-cooled, direct injection | |

| Aspiration | Turbocharged, air-to-air aftercooled | |

| Number of cylinders | 12 | |

| Bore x stroke | 5.51" x 6.50" | 140 mm x 165 mm |

| Piston displacement | 1,860 in³ | 30.48 ltr |

| Flywheel horsepower: | ||

| SAE J1349 | 899 HP | 671 kW |

| DIN6270 | 890 HP | 644 kW |

| Hydraulic fan at maximum speed | 860 HP | 641 kW |

| Rated rpm | 1900 rpm | |

| Governor | All-speed, electronic | |

| Lubrication system: | ||

| Method | Gear pump, force lubrication | |

| Filter | Full-flow and bypass combined |

TORQFLOW Transmission

Komatsu TORQFLOW transmission consists of a water-cooled, 3-element, 1-stage, 1-phase torque converter with lockup clutch and a planetary gear, multiple-disc clutch transmission which is hydraulically actuated and force-lubricated for optimum heat dissipation. Gearshift lock lever and neutral safety switch help prevent accidental starts.

Final Drives

Double-reduction final drive of spur and planetary gear sets to increase tractive effort and reduce gear tooth stresses for long final drive life. Segmented sprocket teeth are bolt-on for easy replacement.

Steering System

PCCS, joystick controlled, wet multiple-disc steering clutches are spring-loaded and hydraulically released.Wet multiple-disc, pedal/lever controlled steering brakes are spring-actuated hydraulically released and require no adjustment. Steering clutches and brakes are interconnected for easy, responsive steering.

Undercarriage

| Suspension | Oscillating equalizer bar and pivot shaft | |

| Track roller frame | Cylindrical, high-tensile-strength steel construction | |

| Rollers and idlers | Lubricated track rollers | |

| K-Bogie Undercarriage | Lubricated track rollers are resiliently mounted to the track frame with a bogie suspension system whose oscillating motion is cushioned by rubber pads. | |

| Extreme Service Track Shoes | Lubricated tracks. Unique seals prevent entry of foreign abrasives into pin-to-bushing clearances to provide extended service life. Track tension is easily adjusted with grease gun. | |

| Number of shoes (each side) | 41 | |

| Grouser height: | ||

| Single grouser | 4.1" | 105 mm |

| Shoe width (standard) | 32" | 810 mm |

| Ground contact area | 11,360 in² | 73290 cm² |

| Ground pressure (Tractor) | 16.2 psi | 112 kPa 1.14 kg/cm² |

| Number of track rollers | 8 | |

| Number of carrier rollers | 2 |

Service Refill Capacities

| Fuel tank | 441 U.S. gal | 1670 ltr |

| Coolant | 72.6 U.S. gal | 275 ltr |

| Engine | 32.0 U.S. gal | 121 ltr |

| Torque converter, transmission, bevel gear, and steering system | 55.5 U.S. gal | 210 ltr |

| Final drive (each side) | 19.8 U.S. gal | 75 ltr |

Operating Weight

| Tractor weight | 184,290 lb | 83590 kg |

| Including rated capacity of lubricant, coolant, full fuel tank, operator, and standard equipment. | ||

| Operating weight | 238,960 lb | 108390 kg |

| Including strengthened Full-U tilt dozer, giant ripper, steel cab, ROPS, operator, standard equipment, rated capacity of lubricant, coolant, and full fuel tank. | ||

| Ground pressure | 21.2 psi | 146 kPa 1.49 kg/cm² |

Hydraulic System

Closed-center load sensing system (CLSS) designed for precise and responsive control, and for efficient simultaneous operation.

Product Parameter

| Model | Komatsu SAA12V140E-3 | |

| Type | 4-cycle, water-cooled, direct injection | |

| Aspiration | Turbocharged, air-to-air aftercooled | |

| Number of cylinders | 12 | |

| Bore x stroke | 5.51" x 6.50" | 140 mm x 165 mm |

| Piston displacement | 1,860 in³ | 30.48 ltr |

| Flywheel horsepower: | ||

| SAE J1349 | 899 HP | 671 kW |

| DIN6270 | 890 HP | 644 kW |

| Hydraulic fan at maximum speed | 860 HP | 641 kW |

| Rated rpm | 1900 rpm | |

| Governor | All-speed, electronic | |

| Lubrication system: | ||

| Method | Gear pump, force lubrication | |

| Filter | Full-flow and bypass combined |

| Gear | Forward | Reverse |

| 1st | 2.1 mph 3.3 km/h | 2.6 mph 4.2 km/h |

| 2nd | 3.9 mph 6.2 km/h | 5.0 mph 8.0 km/h |

| 3rd | 7.0 mph 11.2 km/h | 8.7 mph 14.0 km/h |

| Minimum turning radius | 15'1" | 4.6 m |

| Suspension | Oscillating equalizer bar and pivot shaft | |

| Track roller frame | Cylindrical, high-tensile-strength steel construction | |

| Rollers and idlers | Lubricated track rollers | |

| K-Bogie Undercarriage | Lubricated track rollers are resiliently mounted to the track frame with a bogie suspension system whose oscillating motion is cushioned by rubber pads. | |

| Extreme Service Track Shoes | Lubricated tracks. Unique seals prevent entry of foreign abrasives into pin-to-bushing clearances to provide extended service life. Track tension is easily adjusted with grease gun. | |

| Number of shoes (each side) | 41 | |

| Grouser height: | ||

| Single grouser | 4.1" | 105 mm |

| Shoe width (standard) | 32" | 810 mm |

| Ground contact area | 11,360 in² | 73290 cm² |

| Ground pressure (Tractor) | 16.2 psi | 112 kPa 1.14 kg/cm² |

| Number of track rollers | 8 | |

| Number of carrier rollers | 2 |

| Fuel tank | 441 U.S. gal | 1670 ltr |

| Coolant | 72.6 U.S. gal | 275 ltr |

| Engine | 32.0 U.S. gal | 121 ltr |

| Torque converter, transmission, bevel gear, and steering system | 55.5 U.S. gal | 210 ltr |

| Final drive (each side) | 19.8 U.S. gal | 75 ltr |

| Tractor weight | 184,290 lb | 83590 kg |

| Including rated capacity of lubricant, coolant, full fuel tank, operator, and standard equipment. | ||

| Operating weight | 238,960 lb | 108390 kg |

| Including strengthened Full-U tilt dozer, giant ripper, steel cab, ROPS, operator, standard equipment, rated capacity of lubricant, coolant, and full fuel tank. | ||

| Ground pressure | 21.2 psi | 146 kPa 1.49 kg/cm² |

| Relief valve setting | 3,980 psi | 27.5 MPa 280 kg/cm² |

| Control valves: | ||

| (Spool control valves for Semi-U tilt dozer and Full-U tilt dozer): | ||

| Positions: | ||

| Blade lift | Raise, hold, lower, and float | |

| Blade tilt | Right, hold, and left | |

| Control valves: | ||

| (Spool control valves for variable digging angle multi-shank ripper and giant ripper.) | ||

| Positions: | ||

| Ripper lift | Raise, hold, and lower | |

| Ripper tilt | Increase, hold, and decrease | |

| Hydraulic cylinders | Double-acting, piston | |

| Hydraulic cylinders: Number of cylinders |

Bore | Bore |

| Blade lift / 2 | 7.09" | 180 mm |

| Blade tilt / 1 | 9.84" | 250 mm |

| Ripper lift / 2 | 8.86" | 225 mm |

| Ripper tilt / 2 | 8.86" | 225 mm |

| Hydraulic oil capacity (refill): | ||

| Semi-U tilt dozer | 48 U.S. gal | 180 ltr |

| U tilt dozer | 48 U.S. gal | 180 ltr |

| Ripper equipment (additional volume): | ||

| Giant ripper | 34 U.S. gal | 130 ltr |

| Multi-shank ripper | 34 U.S. gal | 130 ltr |