Product Feature

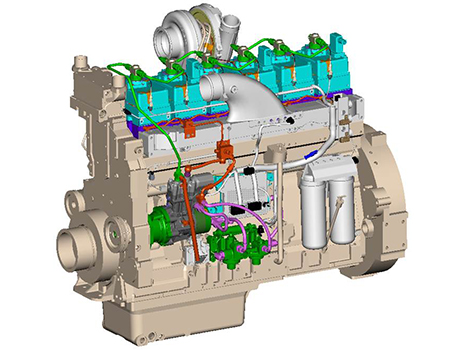

Chongqing Cummins is adoptedQSK19 Electronically controlled engine,Low fuel consumption、Powerful,High reliability and global service you can count on。

The engine is equipped with an advanced modular common rail fuel system(MCRS),The emission meets the requirements of EuropeⅢA/CountryⅢEmission requirements。

CELLON Dual Pre-Filtered Intake System as Standard,Ffectively prevent early failure of engine。

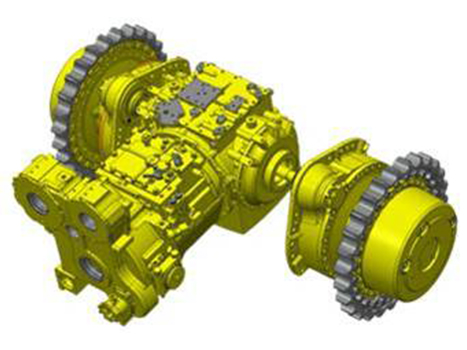

Transmission system adopts modular vibration damping installation.,Convenient for product maintenance。

Hydraulic torque converter with locking function,Output torque may vary with load,And that load adaptability is strong,Hydraulic transmission at low speed,Mechanical transmission at high speed,Can save fuel 10%-15%,High fuel economy。

Normally closed brake,With parking brake function,Can effectively prevent the vehicle from sliding on the ramp,And that safety is high。

Modular final drive,Unattached to the main frame,Can be assembled independently,And is convenient to maintain。

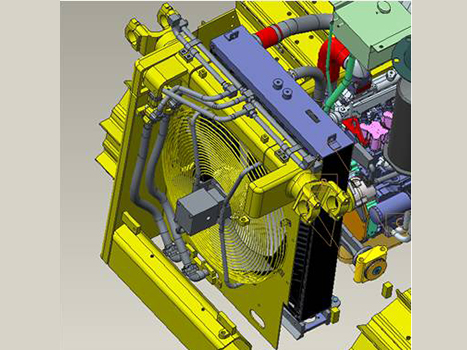

Adopt high pressure hydraulic system,The system pressure is 21MPa,Effectively reduce the physical examination of hydraulic components,The operation micro-mobility is good

Temperature-controlled fan system,Intelligent control of fan speed,Adjust on demand,Improve fuel economy,More energy efficient。

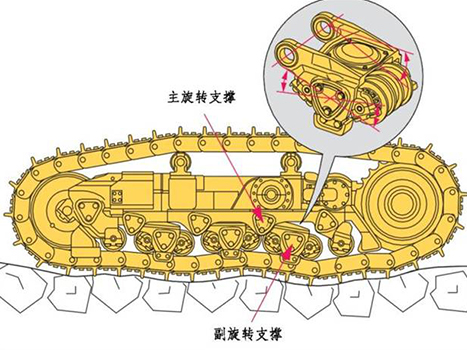

The undercarriage uses rollerKType suspension,With floating walking function,The driving comfort is good;Reduce the rigid impact on the whole machine,And that service life of the whole machine is long;And that road surface has strong adaptability,Increase the grounding area under complex working conditions,The traction performance is good。

Standard 18.5m³Half ofUShovel,Large blade capacity,And that work efficiency is high;High-strength box-type structure and high-performance wear-resistant material,It can easily cope with all kinds of harsh working conditions.。

Giant single-tooth scarifier,It has super penetration.,Can be used for the stripping of rock formation。

Structural parts inherit the excellent quality of Shantui's mature products。

Seamless bellows for electrical harness、Splitter Splitter,High degree of protection。

The core electrical and hydraulic components are imported.,The quality is stable and reliable,The reliability is extremely high。

Collect the key parameters of the whole machine operation from time to times,Fault intelligent monitoring and diagnosis。

The electric control single handle is used for traveling control.,It can realize manual and self-integrated fingertip shift.。

Working device control pilot single handle operation,Flexible operation、Light and comfortable。

Product Parameter

Contrast item |

SD52 -5E(Standard version) |

Performance parameters |

|

Quality of operation(kg) |

70630 |

Net engine power(kw/hp) |

438/588(Minimum fan speed) |

Minimum Turning Radius(mm) |

3864/6786 |

Ground specific pressure(kpa) |

151 |

Engine |

|

Engine model |

Chongqing CumminsQSK19 |

Discharge |

OohⅢA/CountryⅢ |

Form |

In-line、Water cooling、Four-stroke、Turbocharging、Cold in the air、Electrically controlled |

Number of cylinders×Cylinder bore×Travel(mm×mm) |

6×159mm×159mm |

Total displacement(L) |

19 |

Rated power/Rated speed(kw/rpm) |

450/1800 |

Maximum torque(N.m/r/min) |

3019/1300 |

Overall dimensions of the complete machine |

|

Long(mm) |

10390 |

Wide(mm) |

4690 |

High(mm) |

4370 |

Walking performance |

|

Forward/Reverse speed(km/h) |

3.8,6.8,11.8/5.1,9.2,15.8 |

Gradeability(deg) |

30 |

Ground clearance(mm) |

610 |

Transmission system |

|

Transmission form |

Modular hydro-mechanical transmission |

Number of shift gearsF/R |

March 3 |

Torque converter |

Single stage、Single phase、Three elements、With lock-up clutch、The clutch is electrohydraulically controlled、Forced lubrication |

Gearbox |

Planetary gear、Multi-plate clutch、Hydraulic combination、Forced lubrication、Third gear forward、Third gear reverse |

Central drive |

Primary spur gear speed increase、Primary spiral bevel gear reduction、Forced lubrication |

Steering Clutch |

Wet type、Multiple pieces、Spring compression、Hydraulic separation、Linked with the brake |

Brake |

Wet type、Multiple pieces、Spring compression、Hydraulic separation、Linked with clutch、Normally closed |

Final drive |

Primary spur gear、Primary planetary gear reduction、Splash lubrication type |

Chassis system |

|

Suspension mode |

KType suspension |

Track center distance(mm) |

2500 |

Shoe width(mm) |

610(710/810 Optional) |

Grounding length(mm) |

3840 |

Number of track shoes(Unilateral/Piece) |

40 |

Track pitch(mm) |

280 |

Number of riding wheels(Unilateral) |

2 |

Number of rollers(Unilateral) |

7 |

Working hydraulic system |

|

Working pump |

Fixed displacement gear pump,Double-pump confluence mode is adopted,Wherein the pump 1 is a duplex pump,Front pump displacement 135mL/r,Rear pump(Pilot pump)Displacement 10mL/r;Pump 2 Displacement 70mL/r |

Working Valve |

Split-type multi-way valve |

Lift cylinder bore(mm) |

φ150 |

Bore of angle adjusting cylinder(mm) |

φ200 |

Tilt cylinder bore(mm) |

φ225 |

Fuel tank capacity |

|

Fuel tank(L) |

1140 |

Operating hydraulic oil tank(L) |

246 |

Travel hydraulic oil tank(L) |

275 |

Working device |

|

Blade type |

HalfU |

Blade width(mm) |

4690 |

Blade height(mm) |

2250 |

Working capacity(m³) |

18.5 |

Blade lift height(mm) |

1660 |

Shovel depth(mm) |

715 |

Ripper type |

Single tooth |

Loosening depth(mm) |

1105 |

Ripper lift height(mm) |

1435 |

Manipulation form |

|

Walking control |

Electrically controlled |

Work manipulation |

PPC |