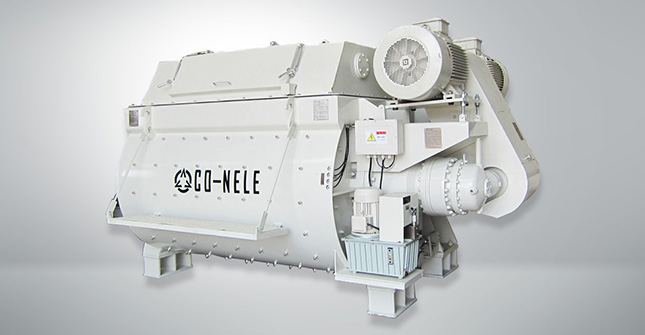

Product Feature

Details

Optimal mixing performance

Intensive mixer can mix high quality mixtures of wide range. Intensive mixer has high mixing speed of mixing rotator and mixer drum. Counter-current mixing can get homogeneous mixture within shortest time.

Low power consumption

Compared with traditional horizontal type of mixer, intensive mixer make the most use of power.

Low abrasion

Anti-wearing alloy liners are installed on the mixer wall and bottom. Mixing blades and scrapers are protected by hard galvalume. Lifespan is ten times than traditional horizontal mixer.

Easy maintenance

Maintenance door is on the mixer drum to make it easy for maintenance and replace wear parts.

MECHANICAL FEATURES

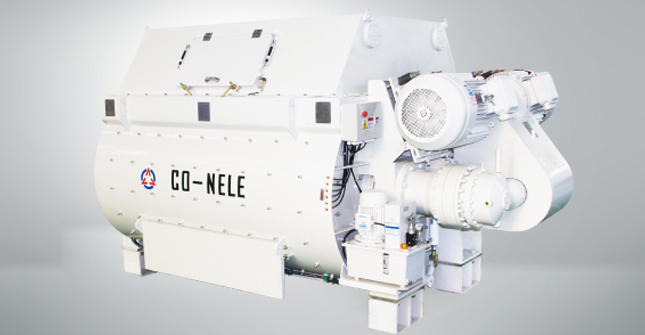

Driving device

It can be selected with different demands on power, mixing speed, rotation direction and energy transmission method for different applications.

Mixing drum can be friction gear or ring gear drive type.

The motor drive the gearbox by vee belt.

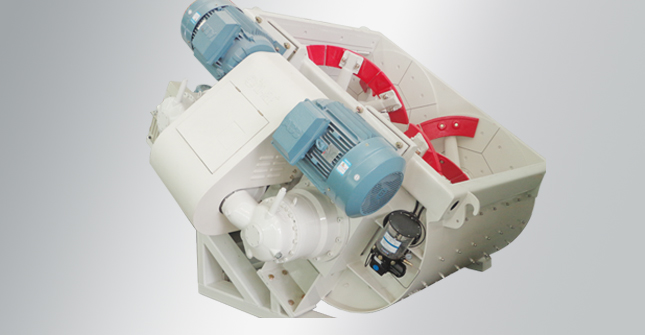

Mixing device

While materials rotating with mixing drum, a force generated between mixing drum and mixing device that is rotating in the same direction on the centrifugal position.

The wolfram carbide compounded liner ensures a durable quality and easy maintenance. The shape and quantity of mixing blade depends on material properties. The blades are also easy to replace.

Maintaining door, safe door and observing port

On the consideration of safety and to the market demand, we adopt reliable high sensitive security switches on the maintaining door.

There is observing port on the maintaining door, observing is possible while mixer is working.

High pressure wash

The high pressure wash is automatic washing device, it can clean mixing device, mixing drum and mixer inside within several minutes. In that case it improves cleaning and save time, keeping optimal performance of the mixer.

Control system

The industrial computer integrated control system can automatically control whole process of material dosing, mixing and discharging.

Product Parameter

Model | CQM750 | CQM1000 | CQM1500 | CQM1500P | CQM2000P | CQM3000P | CQM4000P |

Input L | 1125 | 1500 | 2250 | 1800 | 2400 | 3600 | 4800 |

output L | 750 | 1000 | 1500 | 1500 | 2000 | 3000 | 4000 |

Output mass kg | 900 | 1200 | 1800 | 1800 | 2400 | 3600 | 4800 |

Rotator | 1 | 1 | 1 | 2 | 2 | 2 | 2 |

Scraper | 1 | 1 | 1 | 1 | 2 | 2 | 2 |

Dimension(L*W*H) | 2950*2100*2850 | 3210*2520*2520 |

|

| 4700*2650*2600 | 4900*2850*2650 | 5300*3250*2650 |