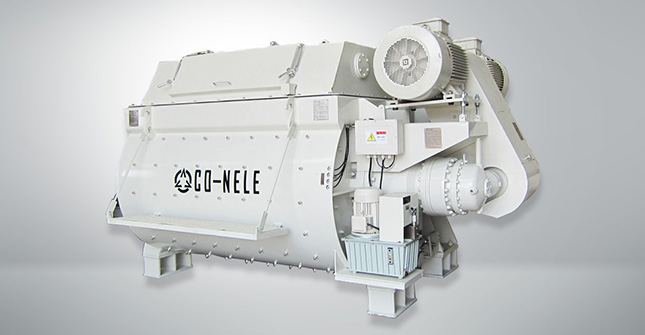

CO-NELE CMP50-CMP750 CMP Planetary Concrete Mixer

Product Feature

Application of planetary concrete mixer

CMP Series Planetary concrete Mixers are manufactured basing on German mixing technology. Capacity range from 50 liters to 4500 liters per batch. It's widely used for mixing precast concrete, concrete block,dry hard concrete, fiber concrete, ultra high performance concrete, refractory material, castble,ceramics, glass and chemicals.

planetary concrete mixer Especially applying to:

◆ HPC(High Performance Concrete)

◆ Low-slump concrete

◆ SPC

◆ CA(Emulsifying asphalt cement mortar)

◆ Etc.

Technical data of planetary concrete mixer

The co-nele planetary mixer consists of 16 models,The minimum capacity is 50L.Capacity from 0.05m³ -5m³.The production capacity ranges from 3m³/h to 240m³ /h.The following is a detailed description of the technical parameters of different models of planetary mixer.

DETAILED DESCRIPTION OF PLANETARY CONCRETE MIXER

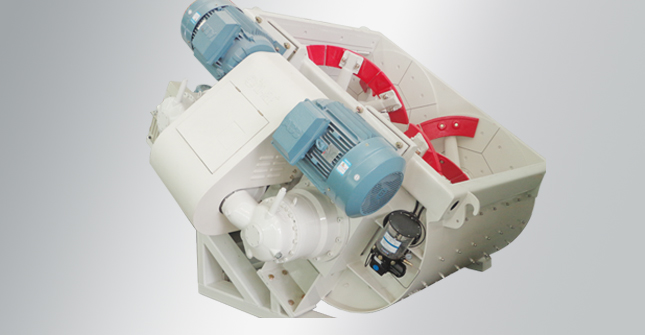

Gearing system

The power transmission is realized by a hard surface gearbox which is designed specially by our company (This technique has been patented). Fluid clutch is installed between the motor and the gearbox (This item is optional). The Fluid clutch can ensure the mixer startup smoothly and it can keep the mixer start up normally even in the full load condition.

The driving force provided by gearbox drives the mixing arms to do not only a revolution but also a rotation, and drives the scraping arms have a revolution. By this drive mode, the mixing action not only has a rotation but also has a revolution, the more complex of the motion track, the more turbulent the mixing is, and then the mixer works more effectively, its mixing more homogeneous.

Mixing device

Driven by the fearing system, the blades fixed on mixing arms and the scrapers on scraping arms crush and overturn the material to complete the compelling mixing.

Motion track

The revolution and rotation speed of the blades have been extensively studied and tested to give the mixer a high output without causing the segregation of materials with different grain size and weight. The movement of the material inside the trough is smooth and continuous. As shown in the picture, the blades track covers the while bottom of the trough after a cycle.

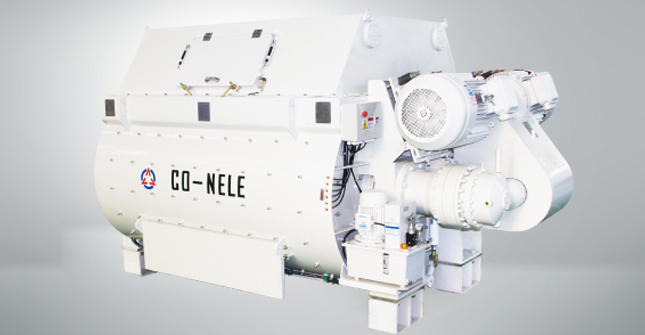

Maintaining Door

According to different demands of customers, there could be three maintaining doors at most. When maintaining, all of them can be opened. Thus it is convenient to maintain. There is also special sealing structure to protect the environment.

Observing Port

There is an observing port on the maintaining door. You can observe the mixing situation without cutting off power.

Security device of the maintaining door

According to the market demands, reliable high-sensitive security switches are used in the maintaining door to make the maintaining work safe and convenient.

Discharging device

According to different demands of customers, the discharging door can be opened by hydraulic, pneumatic. The number of the discharging door is three at most. And there is special sealing device on the discharging door to ensure the sealing reliable.

The hydraulic power unit

A special designed hydraulic power unit is used to provide power for more than one discharging gates. On emergency, these discharging gates can be opened by hand.

Water spray pipe

The special designed sprayer is installed on the water pipe. The spraying water cloud can cover more area and also make the mixing more homogeneous.

OPTION PLANETARY CONCRETE MIXER

The Skip Hopper(lift)

Skip hopper can be chosen according to the requirements of customers. The feeding door automatically opens when feeding, and closes when the hopper begins to descend. The device effectively prevents the dust overflow the trough during the mixing to protect the environment.

Weighing system

According to different requirements we can add aggregate weigher, cement weigher and water weigher.

Temperature and moisture sensor

To ensure concrete and prefabricated parts quality, sensors of temperature and moisture made in Bikotronic of German can be selected.

Control system

The control system can automatically control the process of dosing, mixing, and discharging.

Spare parts

Spare parts can be supplied at any time.

Product Parameter

Item | Model | Model | Model | Model | Model | Model | Model |

CMP50 | CMP100 | CMP150 | CMP250 | CMP330 | CMP500 | CMP750 | |

Out capacity(L) | 50 | 100 | 150 | 250 | 330 | 500 | 750 |

Input capacity(L) | 75 | 150 | 225 | 375 | 500 | 750 | 1125 |

Out mass(Kg) | 120 | 240 | 360 | 600 | 800 | 1200 | 1800 |

Mixing power(Kw) | 3 | 5.5 | 7.5 | 11 | 15 | 18.5 | 30 |

Discharging power(Kw) | 3 | 3 | 3 | 3 | 3 | 3 | 3 |

Planetary/blade | 1/2 | 1/2 | 1/2 | 1/2 | 1/2 | 1/2 | 1/3 |

Side scraper | 1 | 1 | 1 | 1 | 1 | 1 | 1 |

Discharging paddle | 1 | 1 | 1 | 1 | 1 | 1 | 1 |

Weight (Kg) | 700 | 1300 | 1450 | 1600 | 1700 | 2400 | 3900 |

Dimension | 950*786 *1200 | 1664*1453*1447 | 1664*1453*1617 | 1856*1648*1772 | 1862*1850*1870 | 2220*2071*1895 | 2581*2336*2195 |