Product Feature

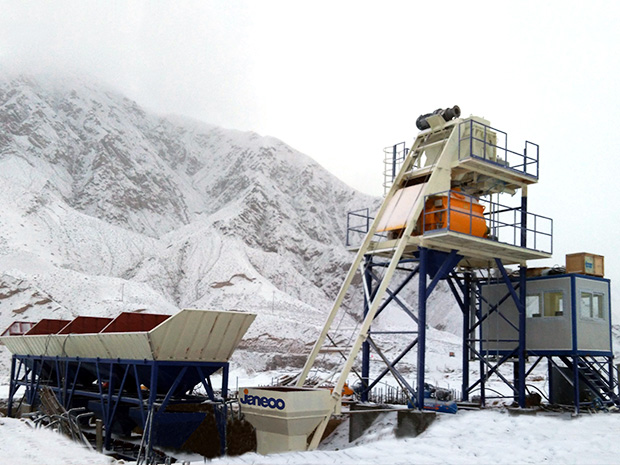

1.The H-shaped steel is used as the installation base frame, and the installation base frame can be connected by different connection forms, and it is more convenient to design different non-standard type mixing plants according to the customer's site conditions.

2.The steel structure type batching machine and the inclined belt conveyor convey the aggregate, which is more stable than the lifting aggregate conveyor.

3.It solves the problem that some customers need to relocate after using the mixing plants or can not dig the concrete foundation due to the hard geology of the site.

4.Greatly save the time and cost of building a station for customers.

Product Parameter

Main Technical Parameters | |||||

Model |

| HZS60W | HZS60W | HZS60W | HZS60W |

Production(m³/h) |

| 60 | 90 | 120 | 180 |

Mixer | Type | JS1000 | JS1500 | JS2000 | JS3000 |

| Power(KW) | 2*22 | 2*30 | 2*37 | 2*55 |

| Output(L) | 1000 | 1500 | 2000 | 3000 |

| Grain Size(mm) | ≤80 | ≤80 | ≤120 | ≤150 |

atcher | Hopper Capacity(m³) | 13 | 15 | 15 | 15 |

| Hopper Quantily(pc) | 4 | 4 | 4 | 4 |

Belt Conveyor Capacity(t/h) | 240 | 240 | 550 | 550 | |

Weighing Scope And Accuracy | Aggregate(Kg) | 4*2400±1% | 4*2400±2% | 4*2400±2% | 4*2400±2% |

| Cement(Kg) | 600±1% | 900±1% | 1200±1% | 1800±1% |

| Aduiterant(Kg) | 200±1% | 300±1% | 400±1% | 500±1% |

| Water(Kg) | 200±1% | 400±1% | 500±1% | 800±1% |

| Admixture(Kg) | 30±1% | 30±1% | 30±1% | 30±1% |

Total Power(kw) | ≈110 | ≈160 | ≈200 | ≈280 | |

Discharge Height(m) | 4.1 | 4.1 | 4.1 | 4.1 | |

Note: 1.The total power does not include the power of screw conveyor;2.The quantity of hopper can be designed as required;3.All above specifications are subject to alteration without notice. | |||||

>