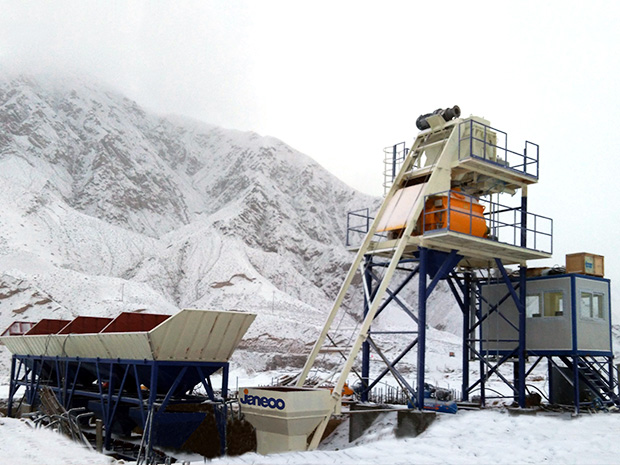

Product Feature

High efficiency、High performance mixing main machine

● Efficient、Energy-saving double-shaft four-spiral stirring main machine。

● High quality power system,Low noise,Long life。

● Large cross area of stirring arm,Better stirring effect。

● The eccentric structure of the stirring shaft does not block the material。

● Beater and Beater Arm 45°Included angle,The flow speed is fast。

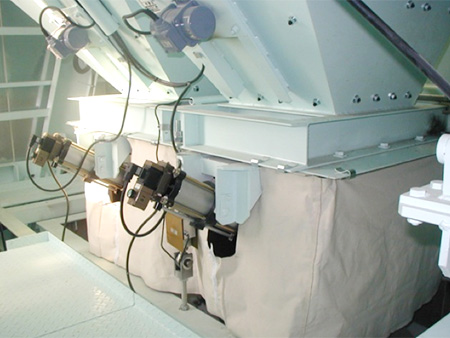

Optimized main engine confluence device

● Put all kinds of materials to the central point of the host machine,Realize the pre-homogenization of material,The stirring is more uniform。

● The water is pressurized by the booster pump and then thrown into the main machine along the periphery of the cover.,The input is more uniform。

● The confluence device is provided with a host monitoring device.,Concrete condition can be monitored。

Modular metrology layer

● The middle storage bin discharge door shall be anti-jamming discharge door.,The blanking is smooth。

● The powder scale is formed by arc folding plate.,Is not easy to accumulate materials。

● Modular in-plant assembly,Better assembly quality。

● All scales in the metering layer are assembled in the factory and delivered.。

● Anti-leakage device for liquid admixture,Leakage prevention after feeding,Overdose prevention during metering。

High environmental protection performance

● All feeding points are of sealed design.,Prevent dust from overflowing。

● Inside the main building, there is a large square forced pulse back blowing dust collector.,The dust removal effect is remarkable。

High intelligent control system

● Multi-point monitoring can be realized,In particular, the main machine and the discharge hopper are provided with real-time monitoring,The slump and homogeneity of concrete can be observed at any time.。

● Have guidance、Simulation function。

● The operation panel can diagnose the equipment fault by itself and propose solutions to the fault.。

High intelligent control system

● Volume up to 6m³,The main mixing machine can realize continuous operation。

● Mechanical volume ruler is arranged inside,Facilitate vehicle scheduling。

● Volume up to 6m³,The main mixing machine can realize continuous operation。

● The storage hopper is provided with a monitoring camera.,Real-time monitoring。

High efficiency pneumatic conveying system

● Design of lifting and conveying pipeline that can be switched freely。

● Greatly improve the conveying capacity of powder。

● More flexible powder silo layout。

● Unique pneumatic system construction,Shorter installation cycle。

Product Parameter

Contrast item |

(2019 edition) |

Discharge height (m) |

4.2 |

Power of the whole machine (KW) |

340 |

Theoretical productivity |

240m³/h |

Type of batching bin |

Four buckets of ground storehouses |

Conveying capacity of belt conveyor(t/h) |

650 |

Parameters of mixing main machine |

|

Model |

SjJS3000GA |

Drive power(Kw) |

2×55 |

Discharge capacity |

3000L |

Maximum aggregate size(Gravel/Pebbles)mm |

≤60/80 |

Weighing range and metering accuracy |

|

Aggregate(kg) |

2×(3000±2%) |

Cement(kg) |

1800±1% |

Fly Ash (kg) |

750±1% |

Water(kg) |

800±1% |

Admixture (kg) |

50±1% |