Product Feature

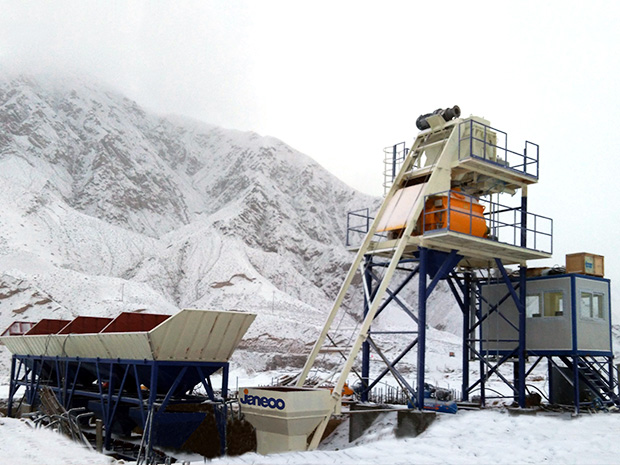

Modular structure

● The main structure is divided into main outrigger、Mixing Unit、Metering unit、Lifting track、Ladder composition,Quick installation、Convenient。

● And that wind resistance level is high。

Reliable aggregate batching system

● Large capacity aggregate bin,The upper part is provided with a screen,Prevent oversize materials from entering the system,Ensure reliable operation of equipment。

● Optimized Design of Eccentric Discharge Gate,Prevent the sand and gravel from being stuck,Realize reliable opening and closing of the charging door。

● A material door adjusting device is arranged at the discharge port.,Change the caliber of the batching feed opening,Realize the adjustment of feeding flow。

● Hinged lining plate structure is adopted for vibration arch breaking.,Ffectively prevent the sand silo from arching,It is suitable for materials with high mud content and water content.。

High efficiency mixing main machine

● The overall form of the stirring device is of a discontinuous spiral structure.,The resultant motion along the radial and axial directions produces a circulating spatial solid stirring trajectory,O that the materials are fully mixed,The stirring performance is fully guaranteed.。

● Internal lining plate of mixing main machine、The blade is made of alloy wear-resistant cast iron,Long service life。

● The mixing device can meet the requirements of concrete mixing,Adopt various arrangement form,Meet the mixing requirements of various high performance concrete。

High precision metering system

● Three-point hanging structure is adopted for the aggregate weighing scale.,Coarse and precise weighing and dithering technology shall be adopted for aggregate measurement.,And that measurement precision is high。

● The powder scale adopts a unique draw-bar scale structure.,And that anti-interference capability is strong,The stability is good,And that measurement precision is high,It is suitable for construction under various severe working conditions.。

● Water、Admixtures shall be measured by coarse and fine weighing.,It can meet the high-precision metering requirements of various additives.。

Air control system with reasonable layout

● Equipped with large displacement air compressor and air storage tank,The operation is more stable。

● Selection of high-quality pneumatic components,Performance is more reliable。

High-speed railway Application Technology

● Based on Siemens industrial computer,The production control software adopts the most advanced automatic compensation scale in China.、Buckle scale technology,To ensure that the measurement accuracy of various raw materials meets the technical requirements of high-speed railway construction。

● Fully-sealed discharge door of arc-shaped aggregate storage bin,Meet the secondary feeding and stirring process of high-speed railway.。

● All materials can be measured by coarse and fine weighing.,Meet the construction requirements of high-speed railway。

Product Parameter

Contrast item |

SjHZS50E-5B |

Discharge height (m) |

4.2 |

Power of the whole machine (KW) |

130 |

Theoretical productivity |

75m³/h |

Type of batching bin |

4*8 |

Conveying capacity of belt conveyor(t/h) |

300 |

Parameters of mixing main machine |

|

Model |

JS1500 |

Drive power(Kw) |

2×30 |

Discharge capacity |

1500L |

Maximum aggregate size(Gravel/Pebbles)mm |

≤60/80 |

Weighing range and metering accuracy |

|

Aggregate(kg) |

4×(3000±2%) |

Cement(kg) |

800±1% |

Fly Ash (kg) |

200±1% |

Water(kg) |

300±1% |

Admixture (kg) |

30±1% |