Global-CE >

Concrete Mixing Plant >

XGMA Concrete Mixing Plant >

XGMA Stationary Concrete Batching Plant

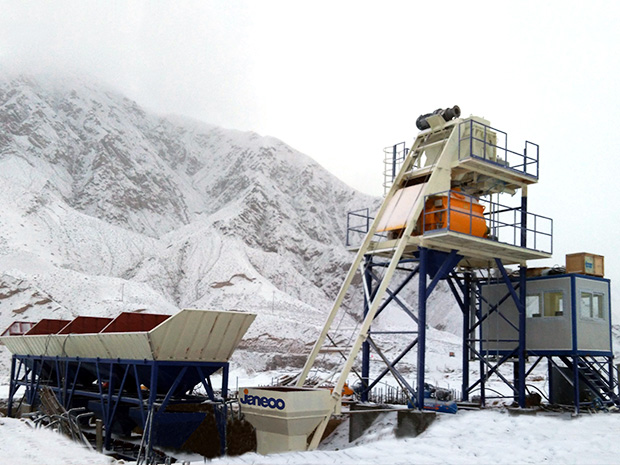

XGMA Stationary Concrete Batching Plant

Mixing Cycle (s):

72(60)

Product Feature

To meet the general requirements of most railways, highways, airports and docks, we adopt modular design. Our machine occupies a small area, and it is convenient for installation and moving. The customers can choose whether to configure external package and dust collecting device or not, as well as other configurations.

Product Parameter

| Models | HZS50(60) | HZS75(90) | HZS100(120) | HZS150(180) | HZS200(240) | ||

| Production (m3/hr) | 50(60) | 75(90) | 100(120) | 150(180) | 200(240) | ||

| Models | JS1000 | JS1500 | JS2000 | JS3000 | JS4000 | ||

| Mixing Power (kw) | 2×22 | 2×30 | 2×37 | 2×55 | 2×75 | ||

| Mixer | Output (m3) | 1 | 1.5 | 2 | 3 | 4 | |

| Aggregate Size (mm) | ≤60 | ≤80 | ≤120 | ≤150 | ≤150 | ||

| Hopper Capability(m3) | 13 | 15 | 18 | 25 | 30 | ||

| Hopper | Hopper Quantity | 3月4日 | 3月4日 | 3月4日 | 3月4日 | 3月4日 | |

| Mixing Cycle (s) | 72(60) | 72(60) | 72(60) | 72(60) | 72(60) | ||

| Conveyor Capability (t/hr) | 200 | 300 | 400 | 600 | 800 | ||

| Scope and Precision of Weighing | Aggregate (kg) | 2500±2% | 3500±2% | 4500±2% | 7000±2% | 2×4500±2% | |

| Cement (kg) | 600±1% | 900±1% | 1200±1% | 1800±1% | 2400±1% | ||

| Fly ash (kg) | 200±1% | 300±1% | 400±1% | 600±1% | 800±1% | ||

| Water (kg) | 300±1% | 500±1% | 600±1% | 800±1% | 1000±1% | ||

| Additive(kg) | 20±1% | 20±1% | 30±1% | 30±1% | 100±1% | ||

| Total Power (kw) (without screw conveyor) | ≈92 | ≈108 | ≈118 | ≈172 | ≈230 | ||

| Discharge Height (m) | ≥3.9 | ≥3.9 | ≥3.9 | ≥3.9 | ≥3.9 | ||