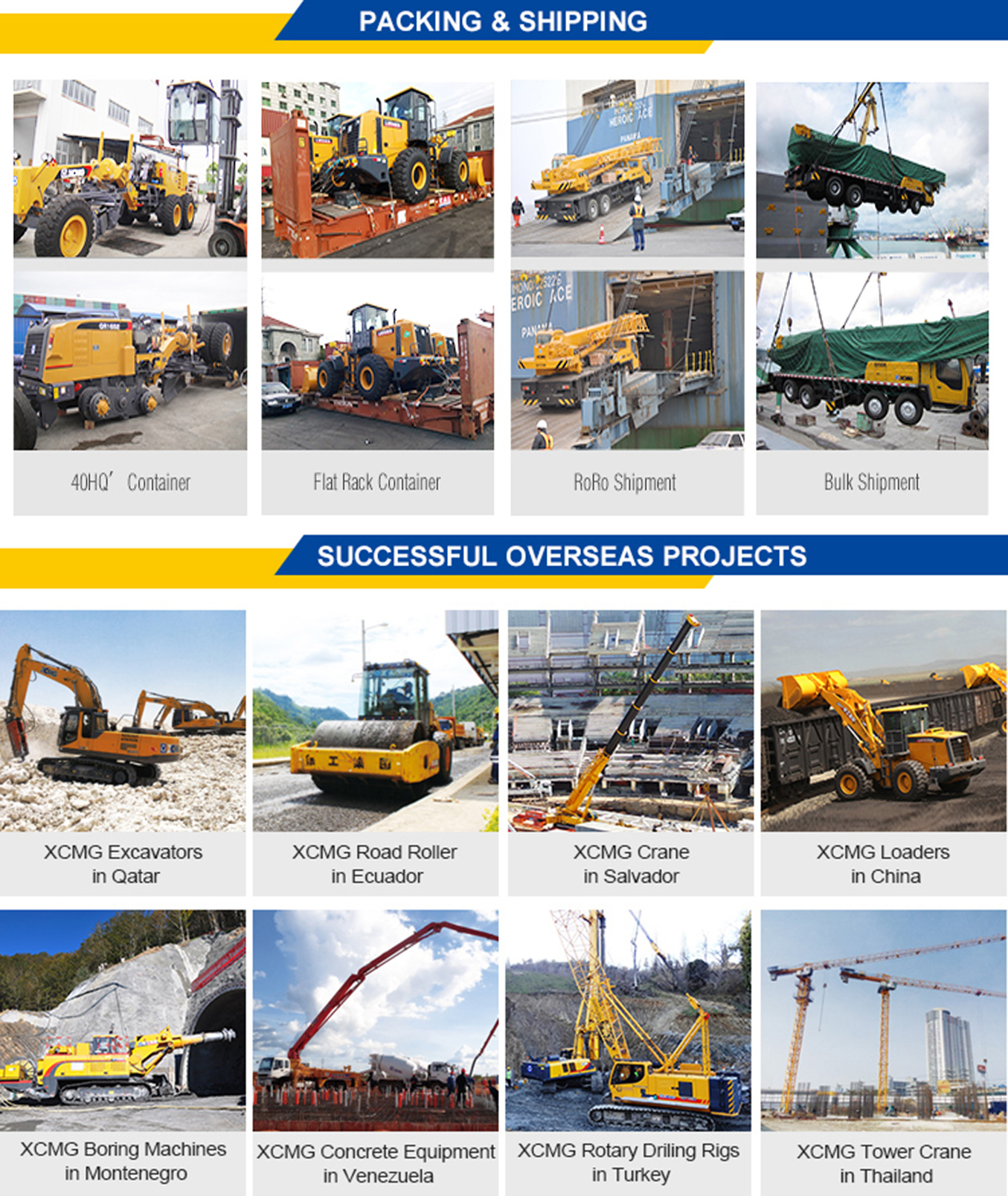

Xcmg 100 Ton Crawler Crane Xgc100 For Sale

Product Feature

Product Parameter

XCMG 100 ton multifunction crawler crane XGC100

Inheriting the advantages from the old generation product, XGC100 crawler crane pays more attention to the improvement of lifting performance, assembly/disassembly and transport convenience and operation comfort. It will bring new experience to customers with multiple outstanding features such as new appearance, industry leading lifting capacity and perfect self-assembly and disassembly function. This crawler crane can be used for farmland construction and water conservancy construction, petrochemical & power engineering, iron and steel, non-ferrous metals, coal and other resource exploration and construction, building construction, municipal construction, port construction and other fields.

1.Electric control system

Intelligent computer integrated programmable control system is the key technology of the crane. PLC programmable controller is used, in combination with conventional electrics, to realize logic control and electronic proportional control of the system, and to improve safety, reliability and efficiency for crane operation. Crane operation can be shown by a larger computer display, easy for man-machine interaction.

2.Hydraulic system

Hydraulic system uses pilot control,open type circuit combination, divided power controI variable pump, LUDV valve control flow adjust, featuring less enengy loss and higher working efficiency.

3.System combination

Hydraulic system is combined with main oil circuit, control oil circuit and auxiliary oil circuit. Main oil circuit controls main movements such as lifting, luffing, slewing and travel, auxiliary oil circuit is used for functions such as assembly, auxiliary movement, radiation, etc.

4.Hoist winch

Main/auxiliary winch has built-in speed reducer with independent drive, and oii supplied by combination of two pumps, main hoist winch is installed with high- strength boIt on turntable and auxiliary hoist winch installed with pin shaft on boom base to reduce basic machine transport weight. Main and auxiliary winch can be exchanged with each other. Speed reducer gas disc type constant closed brake with oil-bath lubrication for safe and reliable work without maintenance.

Item | Unit | Parameter value |

Parameter Item | - | XGC100 |

Operation performance parameter | * | |

Max. rated lifting capacity for boom | (t) | 100 |

Max. rated lifting capacity for fixed jib | (t) | 15.6 |

Max. rated lifting capacity for luffing jib | (t) | — |

Max. load moment | (t.m) | 575 |

Max. rated lifting capacity for tower jib | (t) | — |

Max. rated lifting capacity for boom single top | (t) | 13 |

Max. rated lifting capacity for special jib | (t) | — |

Dimension parameter | * | |

Boom length | (m) | 19~73 |

Boom luffing angle | (°) | 30~81 |

Fixed jib length | (m) | 13~25 |

Tower jib length | (m) | — |

Max. dimension of single unit in transport state(L×W×H) | (m) | 10.5×3.0×3.35 |

Fixed jib offset angle | (°) | 15,30 |

Special jib length | (m) | — |

Speed parameter | * | |

Max. single line speed for hoist mechanism | (m/min) | 110/120 |

Max. single line speed for boom luffing mechanism | (m/min) | 34/46 |

Max. single line speed for jib luffing mechanism | (m/min) | — |

Max. slewing speed | (r/min) | 1.4 |

Max. travel speed | (km/h) | 1.3 |

Grade ability | (%) | 30 |

Mean ground pressure | (MPa) | 0.087 |

Max. single line speed for tower jib luffing mechanism | (m/min) | — |

Max. single line speed for superlift luffing | (m/min) | — |

Engine | * | |

Model | - | SC9DK270G3/QSC |

Engine power | (kW) | 200/183 |

Emission | - | National III/EU III |

Mass parameter | * | |

Overall crane mass | (t) | 104.5(main hook, 19m boom) |

Max. mass of single unit in transport state | (t) | 32.5 |