Hitachi Haul Truck EH3500AC-3

Product Feature

AC-Drive technology

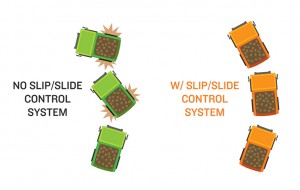

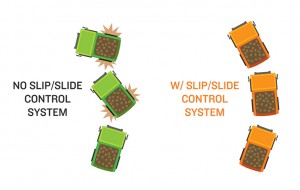

The enhanced Slip/Slide Control System is an active traction control and anti-lock brake system in slippery conditions.he final drive.

The enhanced Slip/Slide Control System is an active traction control and anti-lock brake system in slippery conditions.he final drive.

The pitch control feature of the Advanced AC-Drive System reduces bouncing/ rebounding on the truck as it hits bumps or uneven ground on the haul road.

The pitch control feature of the Advanced AC-Drive System reduces bouncing/ rebounding on the truck as it hits bumps or uneven ground on the haul road.

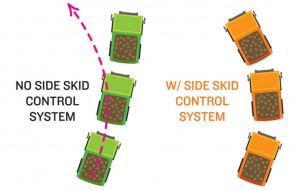

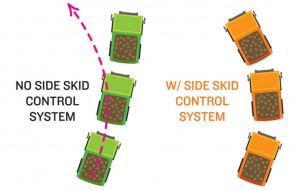

The side skid control feature helps the operator in slippery road conditions when making turns.d back to the final drive.

The side skid control feature helps the operator in slippery road conditions when making turns.d back to the final drive.

The Hitachi Double Path Tandem Planetary Design provides high efficiency. Better component and lubricant life is the result of holding the first carrier stationary and constantly cycling the lubricant through a cooler and filter.

The Hitachi Double Path Tandem Planetary Design provides high efficiency. Better component and lubricant life is the result of holding the first carrier stationary and constantly cycling the lubricant through a cooler and filter.

The new-generation Hitachi IGBT system outperforms previous and competitive systems through its simplicity, improved efficiency, and enhanced dependability. It couples the best GTO features with higher torque, faster acceleration, smoother retardation and lower operating costs.

Superior electric braking enables the driver to stop the truck using the electric brake pedal only with the exception of emergencies.

IGBT modules (inverter and chopper) are liquid cooled. Grid resistors, alternator and traction motors are forced-air cooled. The final drive gear oil is circulated, air-cooled and filtered before being directed back to the final drive.

Engine

The EH3500AC-3 is equipped with a Cummins QSKTA50-CE diesel engine that generates 1491 kW (2,000 hp) at 1,900 rpms and meets Tier 2 EPA emission requirements.

Durable structure and undercarriage

Our new cab structure provides improved safety and durability. The cab frame is stronger and features a three-point isolation-mount design to allow additional independent motion from the truck frame.

Our new cab structure provides improved safety and durability. The cab frame is stronger and features a three-point isolation-mount design to allow additional independent motion from the truck frame.

The frame on the EH3500AC-3 has been redesigned and improved for longer life. The bolt-on high-arch cross member, combined with new rear axle housing and nose cone designs give the EH3500AC-3 the sturdiest frame of all.

The updated body is stiffer and tougher with a 6 percent steeper floor pitch to reduce spillage and provide solid, well-cushioned body-to-frame support.

The new frame has fully fabricated box-section rails with section height tapered from rear to front. The one-piece top and bottom flanges eliminate cross member tie-in joints. The large radii at frame junctions minimize stress, and all welds are longitudinal to reduce stress cracks and deliver more strength and durability.

Suspension

Each spindle is controlled by a hydraulic steering cylinder, which rotates around the king-pin and the outer end of the trailing arm to position the wheels for steering. The spindles are attached by one tie-rod.

The king pin retains the spindle to the trailing arm. Spindle rotates around the king-pin, which is locked in position. The Neocon-E™ strut attaches to the top.

The trailing arm is the main suspension member to which other suspension components are attached. The trailing arms hinge on a torque tube that is clamped to the front of the frame.

The neocon strut is the energy absorption and release component of the ACCU-TRAC suspension system. Pinned to ball bushings at the frame and at the top of the king-pin to prevent bending movements from transferring to the strut. Receives only axial input.

Hydraulics

The improved hydraulic hoist system delivers faster raises and lowers. Hoist raise calibration system can be programmed to cut out the cylinder extension prior to reaching full extension. It also controls the body lowering speed to ensure maximum cylinder life.

Simple controls

The EH3500AC-3 is built with an improved payload monitoring system with enhancements to handle rugged loading conditions better. It is fully integrated to the truck’s monitoring system for prompt reporting of tons moved, cycle times, cycle count and distance.

The high-efficiency dashboard puts controls within easy reach and good visual contact. A full complement of easy-to-read gauges, a spacious environment, six-way adjustable operator’s air seat, tilt/telescopic steering wheel and filtered adjustable air vents contribute to operator comfort.

Comfortable cab

The new HI-TECH ROPS/FOPS cabs are equipped with a Hitachi controller and a large, centrally mounted color Liquid Crystal Display (LCD) as used in our large size excavators. The display makes operation simple and easy.

Visibility from the cab is enhanced with added mirrors, cameras for blind spots, backup and tire lights and brighter headlamps. An analog monitor mounted to the dashboard to display live camera information is included as a standard safety measure.

The EH3500AC-3 features a new, easy-access diagonal ladder that provides a safe, quick way to get in and out of the cab.

The new, wider cab also has a double full-size seat available that provides plenty of space for a trainer to work with an operator.

Double-wall construction of inner and outer steel panels produces a more structurally sound cab. A three-point rubber isolation-mount design allows greater independent motion from the truck frame, which significantly reduces shocks, vibrations and noise, and keeps operators more comfortable.

Heating/cooling capacities have been increased to keep operators comfortable and productive in all types of weather.

Easy to maintain

The AC-drive system has multiple controls that ensure trouble-free reliability and less maintenance, including a grid dry motor control and a blower control that cools the alternator and wheel motors in hot conditions.

The AC-drive system has multiple controls that ensure trouble-free reliability and less maintenance, including a grid dry motor control and a blower control that cools the alternator and wheel motors in hot conditions.

The EH3500AC-3 features a fast-fill system station that gives you direct access at ground level for fast filling/ topping off of lubricants, grease, hydraulic oil and engine oil. Our auto-lube system provides consistent lubrication to required areas on the truck reducing maintenance downtime. (Couplers are optional.)

The EH3500AC-3 features a fast-fill system station that gives you direct access at ground level for fast filling/ topping off of lubricants, grease, hydraulic oil and engine oil. Our auto-lube system provides consistent lubrication to required areas on the truck reducing maintenance downtime. (Couplers are optional.)

Four, low maintenance air filters with evacuator valves bring easy and safe maintenance.

Four, low maintenance air filters with evacuator valves bring easy and safe maintenance.

The collapsible step and flat service stage inside the rear axle brings higher serviceability and safety.

The collapsible step and flat service stage inside the rear axle brings higher serviceability and safety.

The box section design of the frame features one-piece top and bottom flanges that eliminate cross-member tie-in joints and provide a large, exposed center area for quick access to major components.

Simple sight glasses on the fuel and hydraulic fluid systems allow for a quick pre-shift confirmation that the levels are not below minimums.

Our service tool allows downloads of a wide variety of information to your technicians’ laptops for quicker diagnosis of performance issues.

Remote Machine Management

With Global e-Service, an online machine management system, you can access each on-site machine from a PC in your office. You can get its operating information and location to increase productivity. Operating data and log are sent to a Hitachi server for processing, and then to customer and dealers. This system is available 24/7/365.

Product Parameter

| Engine Manufacturer | Cummins |

| Engine Model | QSKTA50-CE |

| Displacement | 50.3 ltr 3070 Inches³ |

| Rated Speed | 1900 rpm |

| Engine Output - Net | 1398 kW 1874 hp |

| Engine Output - Gross | 1491 kW 2000 hp |

| Transmission Manufacturer | Hitachi |

| Speeds - Forward | 1 |

| Front Suspension - Type | Trailing Arm |

| Rear Suspension - Type | A-Frame |

| Tyre Size | 37.00 R57 |

| Service Brake - Actuation | Hydraulic |

| Parking Brake - Type | Disc |

| Retarder - Type | Electronic - Blown Grid |

| Length - Overall | 13560 mm 534 inches |

| Height - Max | 7000 mm 276 inches |

| Width - Over Tyres | 6860 mm 270 inches |

| Hoist - Type | Twin, 3-stage |

| Power Down | Yes |

| Fuel Tank | 2040 ltr 538.9 gallons (US) |

| Hydraulic System | 750 ltr 198.1 gallons (US) |

| Struck Capacity | 80.4 m³ 105.2 yd³ |

| Heaped Capacity | 117 m³ 153 yd³ |

| Gears - Forward / Reverse | 1F - 1R |

| Payload | 181000 kg 399036.2 lbs |

| Gross Vehicle Weight | 322000 kg 709888 lbs |

The enhanced Slip/Slide Control System is an active traction control and anti-lock brake system in slippery conditions.

The enhanced Slip/Slide Control System is an active traction control and anti-lock brake system in slippery conditions.

The Hitachi Double Path Tandem Planetary Design provides high efficiency. Better component and lubricant life is the result of holding the first carrier stationary and constantly cycling the lubricant through a cooler and filter.

The Hitachi Double Path Tandem Planetary Design provides high efficiency. Better component and lubricant life is the result of holding the first carrier stationary and constantly cycling the lubricant through a cooler and filter. Our new cab structure provides improved safety and durability. The cab frame is stronger and features a three-point isolation-mount design to allow additional independent motion from the truck frame.

Our new cab structure provides improved safety and durability. The cab frame is stronger and features a three-point isolation-mount design to allow additional independent motion from the truck frame. The AC-drive system has multiple controls that ensure trouble-free reliability and less maintenance, including a grid dry motor control and a blower control that cools the alternator and wheel motors in hot conditions.

The AC-drive system has multiple controls that ensure trouble-free reliability and less maintenance, including a grid dry motor control and a blower control that cools the alternator and wheel motors in hot conditions.

The collapsible step and flat service stage inside the rear axle brings higher serviceability and safety.

The collapsible step and flat service stage inside the rear axle brings higher serviceability and safety.