Product Feature

Excellent performance

● In case of side jib,With 18 tons(40000 lb)Enhance capacity。

● Width is 3240 mm(128 in),Easy to transport。

● The fuel system is very reliable,With advanced filtering function,Better tolerance to poor fuel quality(Engine compliance is equivalent to Tier 3/Stage IIIA Emission standards)。

● Kits for cold weather offer even more functionality,Improved cab comfort,And the starting performance of the engine in the cold environment is more reliable.。

Excellent operator comfort and handling

● Hydrostatic transmission provides faster steering respond,Excellent handling on the pipeline。

● Narrow or wide tracks available,In order to optimize the ground conditions at the job sit。

● Heavy-duty chassis system,Able to work in rugged terrain,Has high durability。

● The right-hand joystick is ergonomically designed,All booms、Hook and counterweight functions can be controlled with one hand,Very convenient。

● The cab is very comfortable,Features an air suspension seat and ergonomically designed controls,And a wide field of vision。

● Heating/Ventilation/Air conditioning system improved,Use a canopy type machine,Better circulation of heat around the operator。

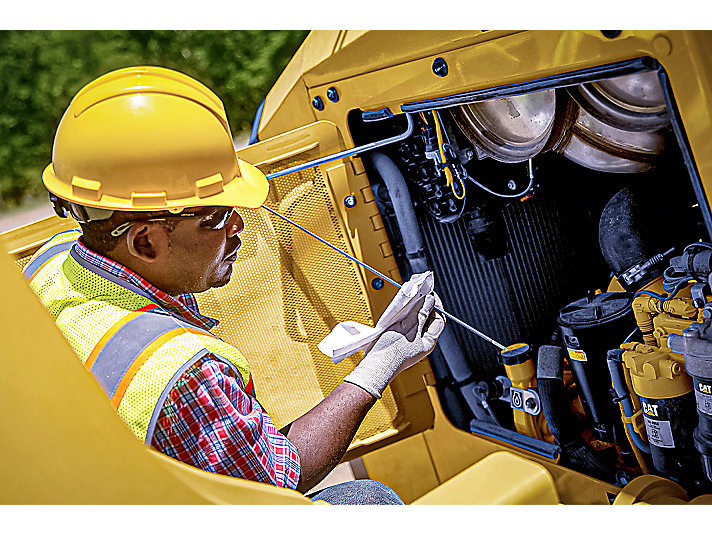

Top service and support

● Global Cat Dealer Network System is aware of pipeline job site needs,Even if the job site is in a remote area,It also provides excellent support.。

● We are the sole supplier of all parts for the purpose built pipelayer,And provide maintenance services for all component。

● And is convenient for maintenance,Easy access to centrally distributed maintenance and diagnostic points。

● Simplify cable replacement - No need to go through the hood。

● Improved cooling package allows for more air flow,This reduces the fan speed to improve efficiency。

● In cold weather,The hydraulic demand fan will slow down,This helps to save fuel。

● Hydraulic reversible fan provides automatic mode or manual mode,The wind direction can be changed,To blow debris out of the radiator core.。

● The machine is equipped with Product Link™,Allows users to monitor remotely,The overall efficiency of equipment cluster management is improved.。

Safety features in the cab

● Rear-view camera with dedicated display,The field of view can be increased,Improve security。

● Load monitoring indicator(LMI)Supplied with the machine,Simplifies the installation of the load monitoring system at the job site。

● Quick-drop release function currently available in other Cat Common in pipelayer models,Improves ease of use。

● The rear window exit is currently Cat Common in the pipelayer product range。

● Roll-over protection structure integrated at the factory(ROPS,Roll Over Protective Structure)Helps protect the operator and machine in the event of a rollover。

Product Parameter

ENGINE |

|

Engine model |

Cat C4.4 |

Note(1) |

All in line Tier 4 Final、Stage IV And South Korea Tier 4 Final Emission standards All off-road diesel engines must Only sulfur content equal to or less than shall be used 15 ppm(mg/kg)Ultra low sulfur diesel (ULSD,Ultra Low Sulfur Diesel), Or use a blend with ULSD of up to B20 Grade Biodiesel。B20 shall comply with ASTM D7467 specification(Biodiesel blend Raw materials shall comply with Cat Biodiesel fuel specifications、 ASTM D67 51 or EN 14214)。Request Use Cat DEO-ULS™ Or comply with Cat ECF-3、API CJ-4 and ACEA E9 Specification of oil。Features about more machines Fuel rating recommendations,Please consult your original Equipment manufacturer。 |

Note(2) |

Cat Selective catalytic reduction(SCR)System Diesel engine tail gas treatment fluid used in(DEF) Must meet International Organization for Standardization(ISO) Requirements specified in the standard 22241.。 |

Note(3) |

(1)The machine adopts Tier 4 Final/Stage IV Emission reduction technology。 |

Engine |

|

Flywheel power |

97 kW |

Net power - 2200 rpm - ISO 9249 |

97 kW |

Net power - 2200 rpm - ISO 9249(DIN) |

132 HP |

Cat C4.4 Discharge |

America EPA Tier 4 Final/European Union Stage IV/Korea Tier 4 Final |

Cat C7.1 Discharge |

Equivalent to Tier 3/Stage IIIA Yes China's Non-road National III Emission Standard |

Fuel tank |

260 l |

DEF Box(1) |

19 l |

Pipe lifting equipment |

|

Enhance capacity |

18144 kg |

Weight - Operating weight |

|

Cab,560 mm (22 in)Shoe(1) |

18090 kg |

Cab,560 mm (22 in)Shoe |

18170 kg |

Cab,760 mm (30 in)Shoe(1) |

18560 kg |

Cab,760 mm (30 in)Shoe |

18640 kg |

Notice |

(1)The machine adopts Tier 4 Final/Stage IV Emission reduction technology。 |

Weight - Shipping weight |

|

Cab,560 mm (22 in)Shoe(1) |

17040 kg |

Cab,560 mm (22 in)Shoe |

17110 kg |

Cab,760 mm (30 in)Shoe(1) |

17510 kg |

Cab,760 mm (30 in)Shoe |

17590 kg |

Notice |

(1)The machine adopts Tier 4 Final/Stage IV Emission reduction technology。 |

Chassis system |

|

Track gauge |

2000 mm |

Grounding track |

2645 mm |

Ground area - LGP |

4.46 m² |

Ground area - Narrow |

3.29 m² |

Ground pressure(1)- LGP |

40.8 kPa |

Ground pressure(1)- Narrow |

53.9 kPa |

Ground pressure - LGP |

40.9 kPa |

Ground pressure - Narrow |

54 kPa |

Shoe/Roller The number of - Each side |

Aug-40 |

Shoe width - Narrow/LGP |

560/760 mm(22/30 in) |

Comment |

(1)The machine adopts Tier 4 Final/Stage IV Emission reduction technology。 |

Size |

|

Host width - Include 760 mm [30 in] Shoe |

2760 mm |

Host width - Include 560 mm [22 in] Shoe |

2560 mm |

Width - When the counterweight is extended |

4750 mm |

Host width - When the counterweight is retracted |

3240 mm |

Host width - Unload Counterweight/After the boom |

3190 mm |

Working length |

3850 mm |

Length - Grounding track |

2645 mm |

Machine height - The top of the winch |

2570 mm |

From the tip of the grouser to the exhaust Machine height at top of tube(1) |

2850 mm |

Height - ROPS Top: Roof/Cab |

2985 mm |

Boom height (SAE 1.22 m [4 ft] When reaching out) |

6220 mm |

DIMENSIONS |

|

Track Gauge |

2000 mm |

Air conditioning system |

|

Air conditioner |

The air conditioning system of this machine Use of fluorinated greenhouse gas refrigerants R134a(Global warming potential = 1430)。 The system contains 1.3 kg of refrigerant, Its carbon dioxide equivalent is 1..859 metric tons。 |