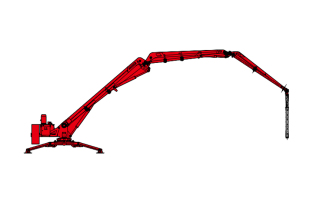

SANY HGY18 Placing Boom

Product Feature

Sany HG18 placing boom is engineered to 18m placing radius. As a mobile

type, the 18m placing boom is dedicated for high-speed rail.

Leading Boom Technology

Finite element analysis

By combining modern design elements such as finite element analysis and structural optimization, our booms have a more intelligent structure, lighter weight, and longer service life.

Hoisting stability test

SANY booms are safe and reliable and won't let you down on the job. Before delivery, each placing boom is subject to strict stability tests to ensure each one is leakage-free, resistant to high pressure, and performance-stable.

Boom system fatigue test

Our SANY self-developed boom fatigue tester carries out strict fatigue tests for our booms in order to guarantee their durability, safety, and reliability.

Intelligent Control

Full-hydraulic control

Our full-hydraulic control technology is appropriate for the entire range of boom movements, featuring stepless regulation of boom operation. It employs a load-sensitive proportional control system with pressure compensation to easily change the running speed of booms. The user has complete speed control by regulating the angle of the control lever, and the boom is able to reach optimal operating performance.

Top-of-the-line intelligent electric control system

SANY booms use German-built Siemens PLC (programmable logic controller), equipped with local control, wire remote control and 100m ultra long-distance remote control. Four frequency bands can be selected with a simple operation, allowing for both comfort and convenience. The quality of our PLC ensures high reliability.

Balance valve controls boom cylinder to guarantee safety

At SANY, we value our users'safety. The balance valve control has precise placing and boom self-locking functions, which effectively prevent accidental falls of booms.

Efficiency and Durability

Rapid Installation

Extensive application of modular design technology and rapid connecting devices allows you to quickly and conveniently install placing booms, helping you to be productive as fast as possible.

Service life extended

Double-layer wear-resistant delivery pipes extend service life up to 30,000-50,000m³, which is 3-5 times the service life of ordinary delivery pipes.

Solution to Any Need

Wide Adaptability

SANY placing booms can solve a wide range of needs, from placing radii of 15 to 41m. Placing booms can be installed on the floor, in an elevator shaft, in a tower, onboard a rig, as a mobile type, dedicated for high-speed rail, and more.

Telescopic supports with space beyond imagination

SANY booms can adapt to different location. For placing booms in elevator shafts, the telescopic supports designed by SANY have an independent climbing system that can satisfy installation in elevator shafts or on curved walls of different dimensions.

Fully automatic stepless lifting of climbing device

For climbing placing booms on the floor, our booms use cylinder. For climbing placing booms within elevator shafts, climbing is jointly fulfilled by fully automatic stepless lifting climbing frame with double electric hoists. No matter where you setup your boom, SANY ensures a fully automatic lifting experience while climbing the boom.

Product Parameter

| Max. placing radius | 18.2m |

| Rotation | ±365° |

| Working ambient temperature | -20℃~+50℃ |

| Installation mode | Free installation of supporting for four outriggers |

| Span between front and rear outriggers | 4900×4900mm |

| Power supply | 380 V 50 Hz |

| Motor model | Y132M-4 B35 IP54 |

| Power | 7.5 kW |

| Rotation speed | 1460 rpm |

| System pressure | 20 MPa |

| Hydraulic oil tank capacity | 100 L |

| Control systems | Radio/Local |

| Pipeline cleaning mode | Water/Dry cleaning |

| Total approx weight | 7.8 t |

| Counterweight | 2.8 t |

| Boom mode | 3R |

| Pipeline diameter | 125 mm |

| End hose length | 3 m |

| 1st section-Length | 7398 mm |

| 1st section-Articulation | 90° |

| 2nd section-Length | 6271 mm |

| 2nd section-Articulation | 180° |

| 3rd section-Length | 4500 mm |

| 3rd section-Articulation | 240° |