SANY Rail-Mounted Container Gantry Cranes

Product Feature

EXCELLENT PERFORMANCE

Auto-tracking and auto-hoisting system ensure safety and improve efficiency

Four frequency conversion anti-sway motors applied to spreader

Soft landing of spreader onto the container increase its service life

Real-time monitoring of the crane’s status on GCP&IEM system shorten downtime

Deflection of the frame will be rectified to prevent rail gnawing of gantry

Dynamic reactive compensation and harmonic suppression maintain the grid stability

Tailored heavy-load frequency conversion driving system for stable movement

Elegant shape, compact structure and appropriate layout

COMFORTABLE OPERATION

Superior inclusive view from the cab ease tension and fatigue of operator

Centralized S+B joystick ensure precise control and convenient operation

Centralized console with appropriate layout and ergonomic design

10.1 inch high-resolution touch screen

Damping suspension seat is comfortable, ventilating and adjustable

Multi-function air-conditioner is anti-fog, defrosting and ventilating

Sound-absorbing and denoising

Radio in the cab

DETAIL HIGHLIGHTS

Gantry mechanism with drives on 4 angles is more efficient and stable

Gantry travelling and trolley traversing mechanisms are optimized

Frame structure with long service life, handrails, skid-proof steps mounted on girder

Wind-protection anchoring system to keep the crane stable

Integrated electric system ensure safe and reliable operation

Environment friendly and energy saving

MANUFACTURE AND DELIVERY

CAE design system, EB electric system, FEA analysis, kinematics and dynamics simulation calculation are applied

Precise processing to all the hinge holes ensure a long service life of all parts

Design and manufacturing of structure all conform to AWS, advanced coating prevents erosion from salt spray

Rigorous test and detection system including fatigue, vibration, control, power etc.

Delivery of RMG crane after assembled is optional

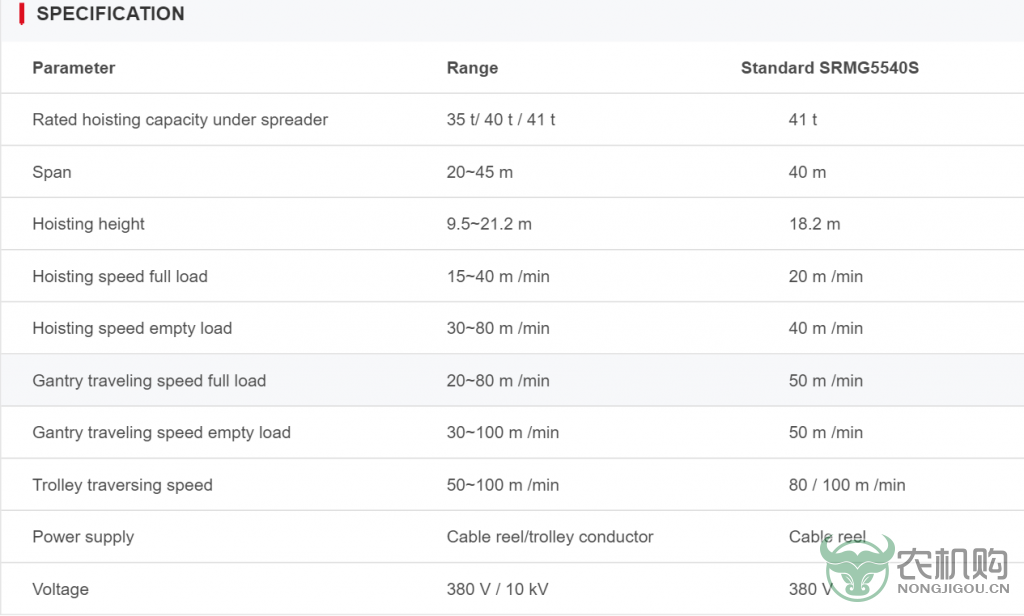

Product Parameter