Product Feature

I. Super chassis with High loading capacity

A. Powerful engine

● Engine type:

Four-cylinder Inline Diesel Engine with 16 valves, Double overhead camshaft, Turbocharged and intercooled, High Pressure Common Rail Fuel Injection System.

● Advanced Technology:

2 ton light truck is equipped with D19TCIE1, euro 5, DEV engine, jointly developed by YUNNEI Power and German FEV Company, strong and reliable, up to 75kw/102hp, with noise reduction, small shaking force and more environmental emission.

● Powerful:

Displacement 1.9L; electronically controlled and water cooling EGR; central injector; spiral& vortex double intake; in-cylinder preheating device. Four cylinders and 16 valves, higher air-intake efficiency brings higher transmission efficiency, more suitable for high speed output. Vacuum control VNT supercharger and large torque reserve, resulting good acceleration performance. The fuel injector is placed in the middle, bringing more precise injection volume and fuller atomization, achieving homogeneous combustion, accelerating the combustion energy supply— further improving the fuel utilization and reducing the fuel consumption.

● Fuel- efficient:

High Pressure Common Rail Fuel Injection System, and Multi-valve promote the fuel burning more sufficiently. Fuel consumption per 100 kilometers is only 4.5L (depending on the actual working condition).

● Reliable and durable:

High-strength alloy cast iron body without cylinder liner; high-strength aluminum alloy cylinder liner, with lower body; round corner rolling and strengthening process for crankshaft; concave camshaft; independent cooling of the body and cylinder liner, and other advanced technologies.

● Safe and Comfortable:

Timing gear& chain transmission system; roller rocker arm; hydraulic clearance adjustment; double overhead camshaft; four valve technology; intake swirl and intake throttling control—greatly reducing engine noise.

B. High-strength rear axle

Adopting the 130 rear axle with equal height gears, the gear torque capacity is increased by 15%, the intensity greater and the life longer; the rear axle speed ratio is 4.875, meeting both the dynamic and economic needs of different users. What’s more, compared with welding forming, stamping forming rear axle is formed with greater strength, higher precision and stronger bearing capacity. And finally, there are a variety of wheelbases (2750/3150mm and 3300mm, double-row cab) and a variety sizes of cargo containers to choose from.

C. Professional frame

High-strength and fully riveted lightweight frame. Adopting high-strength manganese steel; full riveting connection to ensure reliability of heavy load; the longitudinal beam is a variable cross-section straight beam, with a larger section where the bending moment is larger, and a smaller section where the bending moment is smaller; the core position, reinforced by double-layer frame, effectively responds to various sudden increases in stress— while ensuring the strength of frame, 2 ton light truck also reduces the weight of the chassis to the greatest extent, further resulting lightweight and lower fuel consumption.

The front and rear suspension is optimized, and the stabilizer bar is selected to further improve the comfort performance and improve the vehicle's smoothness and stability.

D. High load bearing leaf springs

Simple structure and low cost, your reliable comrade. The front 3 springs, which has the property of stress equalizing and low friction between the plates, and thus can reduce the chassis quality and achieve lightweight, reduce noise, and improve riding comfort. While the rear part adopts multi-leaf springs: 6 main springs and 4 auxiliary springs, which can withstand greater torsion and bending stress and easily support greater load.

Continuously optimized design of leaf spring greatly improves the shock absorption effect and strength, ensuring both the loading capacity and riding comfort.

E. High load carrying tires

Rear twin tires design with high-bearing capacity; 185R15 vacuum radial tires, combined with high-strength steel wheels for trucks— while ensuring load capacity, R15 flat tires can reduce fuel consumption, lower the center of gravity, increase lateral stability and speed up response.

II. Safe and comfortable driving experience

A. Anti-Lock Braking System (ABS) prevents wheels from locking, reduces the slide and prevent slide of side direction of vehicle, during emergency braking, and thus increases braking efficiency, reaching more than 90%. It can also reduce brake consumption, extending the service life of brake drums, discs and tires twice.

B. 65L super-volume fuel tank, reducing the trouble of frequent refueling, and adopts 5-layer high-performance HDPE plastic material, which is safe, portable, clean and rust-free.

C. Matched with LC5T88 improved gearbox, its synchronizer capacity is increased, control force reduces, and control comfort improves. And the manual 5-speed makes you feel more involved in driving.

D. Ultra-low cargo platform. From the user's angle, the low-chassis design fully considers the problems of manual and mechanical loading and unloading. The ultra-low height of the cargo platform, 770mm, is at least 30mm lower than that of competing products, more convenient to load and unload goods and saving both time and labor.

E. Equipped with a large refrigeration air-condition, which far exceeds the performance of other competing products, allowing users to cool off in the hot summer.

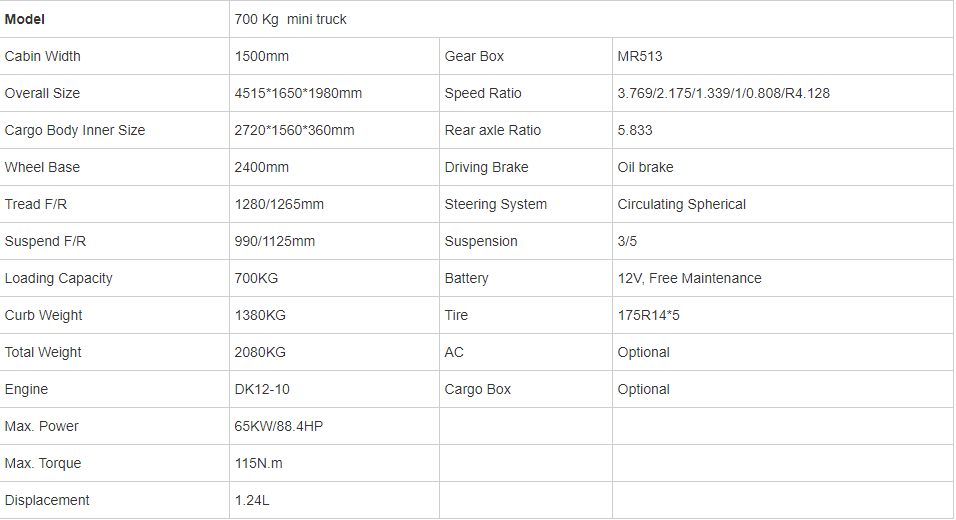

Product Parameter