Zoomlion ZTC350E552 Truck Crane

Product Feature

【ZTC350E552 Parameters of truck crane】

Vehicle weight:38.935t

Length of main arm:44m

Maximum lifting moment of basic boom:1485kN.m

Maximum lifting moment of the longest main boom:870kN.m

Length of auxiliary arm:8m

Maximum lifting capacity of full extension arm:8.1t

Counterweight weight:8.5t

Outrigger across single stage:6.8m

Boom head structure:Veneer head

Jib section:W650 H840

Turntable structure:Double Triangle Structure

【ZTC350EPerformance characteristics of 552 truck crane】

One、Core advantage

Lowest purchase cost、The most cost-effective four-bridge product in the industry,Lower prices give you a higher ROI。On the whole,Superior performance、Powerful、Smart and efficient、Safe and reliable、Comfortable and durable。

1、The longest in the industry is 44 meters.UType a main arm,Maximum operating range;Maximum lifting moment of basic boom 1485KNm,Maximum lifting moment of full boom 870KNm,Maximum lifting load of the longest main boom 8.1t,Industry-leading comprehensive lifting capacity;Industry innovation plate boom head and compact boom tail,Overlapping Ratio Excellence,Boom section up to 50tProduct level,The bearing capacity is strong。

2、Powerful chassis,Equipped with WeichaiWP9H310 engine+Fast 9-speed transmission,Strong driving operation power、Good passability,Strong off-road performance on construction site,There is no construction site that can't be entered.,Have“In truck craneSUV”A good reputation。

3、Adopt omni-directional vehicle information platform,View Device Device Location、Real-time working condition,Quickly obtain equipment operation information、Equipment failure、Maintenance information, etc,Realize three-dimensional monitoring of equipment operation。

4、The fifth outrigger has synchronous retraction function.,To prevent the collision accident caused by the customer forgetting to collect the 5th outrigger;Standard reversing video、Winding surveillance mirror、All-roundLEDLights,The efficiency and safety of the operation are greatly improved.。

5、Have a car-like driving experience,New coating with green environmental protection and fashionable texture,Zoomlion New Generation 4.0 Two rooms,Humanized detail design,Panoramic skylight in the control room,Large space,More comfortable。

Two、Product selling point

1、Strong lifting operation capability

The performance is excellent,Have more than one“The best in the industry”,Industry-leading comprehensive lifting capacity。

(1)The material is the most sufficient,The weight of the whole vehicle is close to 39 tons.;

(2)5 knots up to 44mUShaped main arm,Industry's longest main arm,Maximum operating range;

(3)Maximum lifting moment、Highest lifting capacity:Maximum lifting moment of basic boom 1485KNm,Maximum lifting moment of full boom 870KNm,The maximum lifting capacity of the full boom is 8.1t;

(4)Industry's largest counterweight:Single-stage movable outrigger 6.8mAcross,Secure counterweight 8.5 tons,And that remote lif performance is strong,And that overall stability is good;

(5)Optimum type of structural member,Maximum section of structural member,The strongest carrying capacity。

● Main arm:Longest arm length of products of the same level、The structure is the strongest

(1)OptimizedUShaped section

Section height of jib、Stiffness、The ability to resist lateral bending is significantly enhanced,Up to 50tProduct level。After the boom is extended, it is close to the state of equal strength.,The deformation is smaller,More uniform,The lifting weight is more stable。

(2)Boom box head

Optimized into a novel plate-type head,At lap length、 Under the condition that the basic arm length is constant,Full boom length can be increased by 1mAbove。

(3)Liminate that telescopic vibration of the boom

Boom Fabrication Quality Improvement、Adoption of New Slider Material and Optimization of Its Oil Groove。

● Frame:Large rectangular section、High strength steel plate

(1)Use a more realistic working condition.、Finite Element Optimization Analysis of the Whole Structure of the Vehicle,Higher degree of structural optimization,The results are more accurate;

(2)Optimized large rectangular cross section structures,The rigidity is good,Greater resistance to torsion;

(3)The structure layout is reasonable,The force is uniform,Stronger carrying capacity。

2、Powerful four-axle truck crane chassis

Chassis platform of four-axle heavy-duty truck crane,It has strong bearing capacity.,Good passability、Mobility,Driving reliability。

(1)Carrying capacity of the strongest four-axle chassis,Powerful

WeichaiWP9HFour-valve engine+Shaanxi Gear 9-speed gearbox+Collocation of 13-ton drive axle,Be called “Gold transmission chain”,Perfect match of power transmission, The transmission included angle is arranged in a straight line.。

Use 350HPower platform,The whole machine is satisfiedGClass vehicle standard,Exempt front lower guard,Maximum speed 85Km/h,Gradient 43%,Minimum turn diameter 24m,Minimum ground clearance 260mm,Better trafficability,Strong off-road performance,There is no construction site that can't be entered.,Be called“In truck craneSUV”。

(2)Most enjoyable driving experience,Save money and be comfortable

Total factor optimal design+Numerous calibration tests:Shift force as low as 64N,Decrease 15%;Clutch pedal force as low as 150N,Decrease 15%;Steering force as low as 50N:Decrease 15%。More than improving the design is the repeated polishing of excellence.,Craftsman spirit is an attitude.。

Rubber Spring+VType a thrust rod:It can effectively improve tire grinding.;Maintenance free;And the damping efficiency is high,And that comfort is high;Flexible connection,Better lateral stiffness,Eliminate abnormal noise。

3、Extreme handling performance

Fully upgraded handling performance,Rotary load sensing system,Variable motor is used for lifting.,Working speed、Perfect balance between smoothness of movement and micro-mobility,Lower stable speed、Smooth,Easier installation alignment。

(1)New slewing control technology:Minimum steady speed of swing up to 0..1°/s。

(2)Winding pressure and speed matching technology:Variable motor is used for winch.,The lifting moment is large,No reverse rotation for secondary hoisting of winch、Fretting speed up to 2.5m/min。

(3)Control Technology of Derricking Weight Lowering:There is no pressure oil output from the hydraulic system during luffing lowering,Relying on the dead weight of the boom and the lifted object to realize lowering,Smooth lowering and better micro-mobility,Energy saving under luffing condition 30%。

(4)Second Generation Arbitrary Scaling Technology:Telescopic balance valve setting interlock control,More accurate telescopic action of boom、No synchronous retraction of the boom。

(5)Hydraulic gear pump system:The main pump of the hydraulic system is a quadruple pump.,Power supply according to actual demand,Efficient and stable。

(6)After-valve compensation、Main valve for load sensitive crane:Optimize the feedback oil circuit of the main valve,Lifting system response speed 10%,The composition of any action can be realized.。

(7)Handle control mode optimization:Change telescopic and auxiliary winch switching to telescopic and luffing switching, Control mode is more in line with user habits。

4、Advanced intelligent platform

Adopt omni-directional vehicle information platform,Realize three-dimensional monitoring of equipment operation。

(1)Equipment status monitoring:View the real-time working condition of the equipment,Equipment location。

(2)Historical data report:Quickly obtain equipment operation information,View job and fuel consumption records by date。

(3)Breakdown、Abnormal、Maintenance reminder:Timely access to equipment failure、Abnormal battery and fuel、Maintenance information。

5、Environmental protection and noise reduction

Multiple noise reduction technology,The driving and working noise is superior to the national standard.,Quieter job status、More environmentally friendly、Safer。

(1)Low-speed four-valve engine;

(2)Optimized engine mount design,Reducing engine vibration transmission;

(3)New sound insulation design of engine hood;

(4)The silencer noise reduction technology is adopted for the valve,Reduces brake noise。

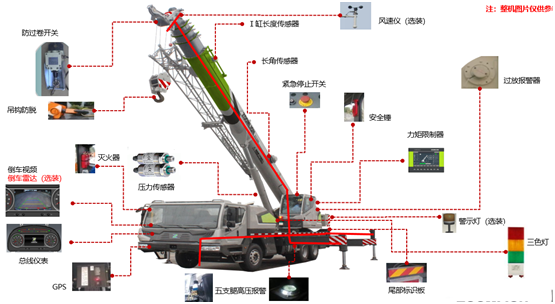

6、All-round security protection strategy

There are 16 kinds of safety protection measures for complete machine control.,Adopt a comprehensive and multi-protection strategy,It can effectively guarantee the safety of operation.。

(1)Fully automatic torque limiter,When the lifting torque reaches the rated 90%Time,Lights、Audible alarm,With fault self-diagnosis function;

(2)Anti-overdischarge alarm:Alarm when the wire rope on the winch is less than 3 circles,Cut off the relevant action;

(3)Anti-overwind switch:Winch height limit,Prevent the hook from damaging the pulley at the head of the boom,Cut off the relevant action;

(4)Tricolor light and sound warning:Remind according to the current safety condition of the truck crane、Alert the personnel in the operation area;

(5)Equipped with winch monitoring mirror、All-roundLEDLights,The efficiency and safety of the operation are guaranteed.;

(6)Standard reversing video,Reversing is visible,Take the distance as you like;Optional reversing radar,Display the obstacle distance behind the vehicle when reversing,Improve the safety of driving operation;

(7)The fifth outrigger has synchronous retraction function.,When retracting either vertical cylinder,The fifth outrigger cylinder retracts synchronously,The collision accident caused by forgetting to withdraw the fifth leg is effectively avoided.。

7、Comfortable and luxurious product experience

New coating with green environmental protection and fashionable texture,Humanized detail design,Large space,More comfortable,Have a car-like driving experience。

(1)Zoomlion New Generation 4.0 Two-room design,Space layout with full 3D man-machine simulation verification,910mmWide Control Room,Equipped with front sliding window and panoramic skylight,The field of vision is wider,Spacious and comfortable。

(2)Optimized boom head and jib,The efficiency of disassembling and assembling the lifting hook and the auxiliary arm is improved,Drive steering、Shift and other control forces are significantly lower than the national standards.,Light and flexible。

(3)Exquisite interior、Power windows,Semi-surround seat,Provide a car-like driving experience,Comes with a rotating machine shed、Flat plate hood,More convenient maintenance and storage。

(4)Elegant and beautiful headlamp,Add a lens;Equipped with winch monitoring mirror and night lighting,Standard reversing video,Optional reversing radar,The efficiency and safety of the operation are greatly improved.。

8、High reliability

Through the analysis of market and customer demand、Analysis of past product failures,Experiencing 10000 times of fatigue tests under simulated working condition、5000 times of rated load condition test、3000 times of lifting test under extreme working conditions、11000kmHigh-intensity driving test,30% improvement in mean time between failure%。

(1)Zoomlion Joins Hands with China Saibao Laboratory,A strong alliance,Create greater value for customers;

(2)Adopt the most advanced reliability design method :29 Modules Refined Reliability Modeling Allocation,UseFMEA、FTAReliability analysis method;

(3)Establish the most authoritative reliability evaluation system;

(4)Overall improvement of reliability of parts and components:48 types of key components to achieve reliability improvement,Component reliability increased by an average of 30 percent%Above。

9、Low operating costs

Maturity、Reliable domestic parts configuration,Obtain the strongest operational capability of 35 tons of products in the industry with lower operating costs。

(1)ZTC350HChassis power,Low fuel consumption during 100 km driving;

(2)Maturity、Reliable localization configuration:Weichai engine+Fast transmission+Double Reduction Bridge,Maturity、Reliable domestic hydraulic system:Main pump+Main Valve,And that maintenance is convenient、The cycle is short,The regular procurement cycle for imported spare parts is 3 months.,The regular procurement cycle for domestic spare parts is 3 days;Half the cost of spare parts,And is convenient to purchase;

The maintenance cost is low;And has strong environmental adaptability。

Product Parameter

Project |

|

|

|

Driving status |

|

|

|

Total mass in running condition |

|

Kg |

38935 |

Get off the vehicle engine model |

|

|

WP9H310E50 |

Engine Power Rating |

|

Kw/r/min |

228/1900 |

**High travel speed |

|

Km/h |

85 |

**Small turn diameter |

|

m |

4 |

**Small ground clearance |

|

mm |

260 |

**A steep climb |

|

% |

43 |

Crane operation status |

|

|

|

**Large rated lifting capacity |

|

t |

35 |

**Large lifting torque |

Basic arm |

kN.m |

1485 |

Boom length |

Basic arm |

m |

11.2 |

**Long main arm |

m |

44 |

|

**Long main arm+Jib |

m |

52 |

|

Mounting angle of auxiliary arm |

|

° |

D/15/30 |

Boom up time of main boom |

|

s |

40 |

Full-extension time of main boom |

|

s |

85 |

Swing speed |

|

r/min |

0-2.5 |

Lifting speed |

Hoisting mechanism of main engine No load |

m/min |

135 |

Auxiliary lifting mechanism No load |

m/min |

120 |