Product Feature

Overview

Our high-efficiency and saving-energy ball mill adopts rolling bearing substituting for sliding bearing, which can save energy 10-20% compared with sliding bearing. Adopting oil grease in place of thin oil lubrication station, and large-type mill needs not to be equipped with high-and-low pressure lubrication station with high cost.

Product Features

1. Grate ball mill is equipped with grid plate which has a high ball load on its discharge end. It has a larger installed power to ensure a high productivity, and its characteristic of rough discharge granulality locates its scope of rough grinding.

2. Overflow ball mill is equipped with no grid plate which determines a low ball load, lower power and productivity, suitable for secondary fine grinding due to its fine granularity feature.

Working Principle

The materials are evenly and spirally fed into the first cabin of grinder trough the hollow shaft from the feeding device, in which there is ladder lining plate or ripple lining plate with different size of steel ball. The rotation of cylinder will generate the centrifugal force which will bring the steel ball to a certain height, and drop down to impact and grind the materials. After the coarse grinding in the first cabin, the materials go into the second cabin, in which there is flat lining plate and steel ball. The materials will be further grinded and are discharged from grate.

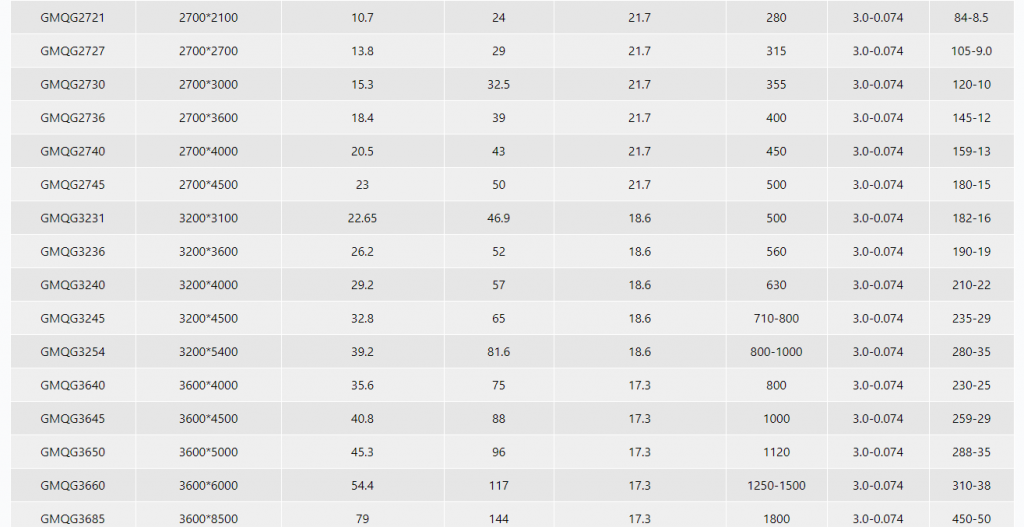

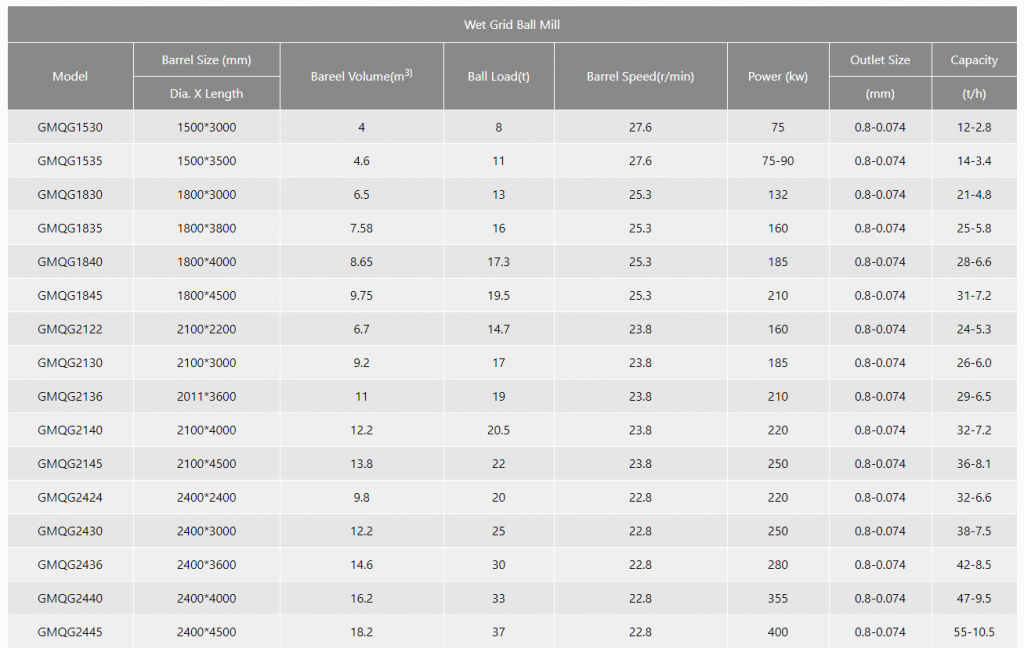

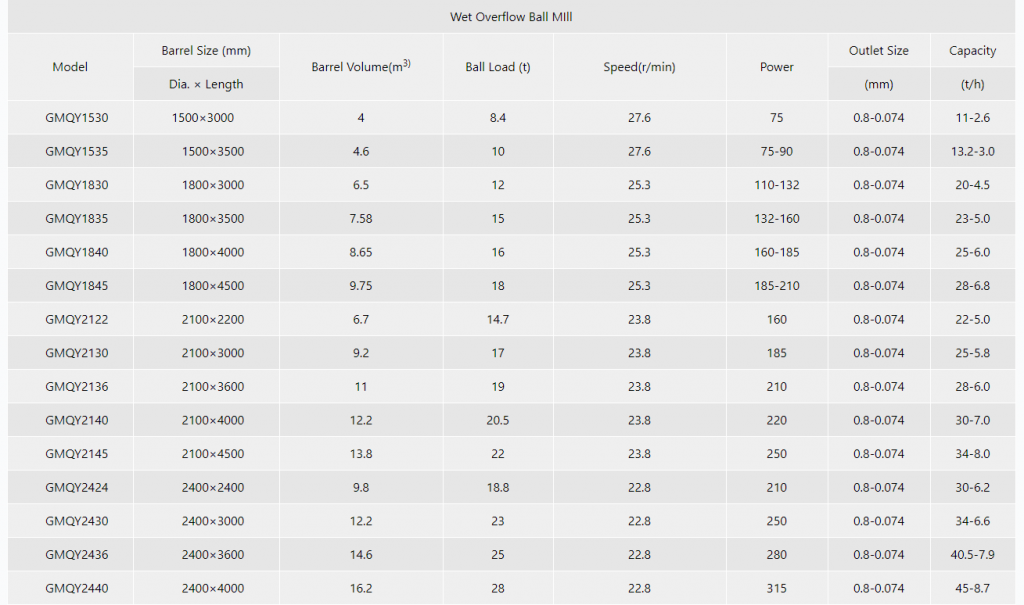

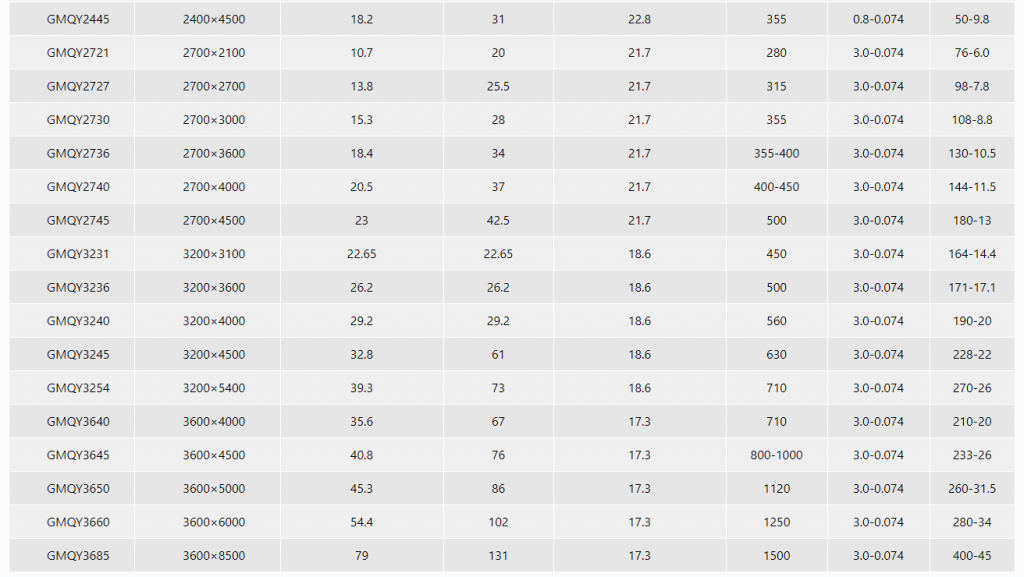

Product Parameter