Product Feature

Equipment introduction

This super micro mill is specializing in the production of super fine powder of the fineness higher than 1000 meshes. Shanghai Jianye managed to develop this machine by absorbing the experience at home and abroad as well as experimenting with more than 12 different designs. The SCM super mill is designed to produce the fine powder and super fine powder of the nonflammable and non-explosive stuffs with the hardness below 6, such as the chalk, the dolomite, the kaolin, the calcite, the mica , the limestone, etc. Due to the advantages like the high efficiency, the stability, the high fineness and the environmental protection, this machine is quite popular in the market.

Working principle

The motor drives the main shaft and different turntables through the reducer. And the turntable rotates with more than ten rollers on the ring. The bulk materials will be lifted to the storage chamber by the elevator after being crushes be the hammer crusher. The vibrating feeder will transport materials evenly to the middle of the top layer. Then, materials will be thrown to the brim by centrifugal forces and fall down. When falling, the materials will be crushed, compressed and grinded by the rollers top to down. The centrifugal blower draws the air into the machine and blows the coarse powder, which has been through the three-time grinding, to the separator. The turbine in the machine will make the unqualified powder fall down for regrinding while the qualified powder will be blown to the cyclone collector and then be discharged as finished products. And the air flow, which still carries some dust will be cleaned by the dust cleaner and then be released.

Equipment advantage

1.efficient

When the fineness of finished products is the same, the output of superfine grinding machine is 40% higher than that of air flow mill and stirring mill;

2.The wear parts of ultra-fine grinding are highly utilized

For the same fineness and raw materials, the wearing parts of this mill can last for a much longer time than that of the impact crusher or the turbine crusher, which could be more than one year.

3.Safety and reliability

There is neither screw nor rolling bearing in the chamber so that there is no abrasion on bearings or sealing parts, nor the screw loosening.

4.The superfine grinding machine has high fineness

The fineness could reach d97?5um for the first time.

5.Environmental protection

The dust cleaner and silencer is helpful to reduce the noise and pollution, which could meet the National Environmental Protection Standard.

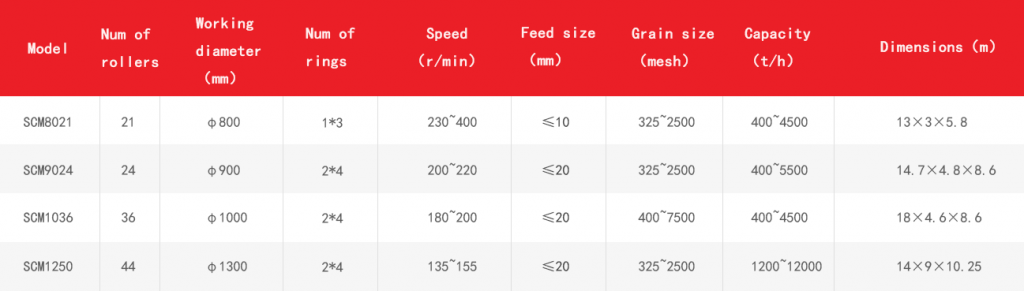

Product Parameter