Product Feature

Equipment introduction

This high pressure grinder mill is the improved type of the traditional Raymond mill. It is good to grinder the nonflammable and non-explosive material of the hardness below 9.3 Mohs and the moisture below 6% such as the barite, the limestone, the ceramic and the slag. Due to the stable performance and the high productivity, this machine mill has been popular in the industries like mining, metallurgy, chemical industry, construction materials. Shanghai Jianye has several models to cover the range of the fineness, from 60 to 1250 meshes. And it even can reach the extreme fineness of 2500 meshes. Besides, it can even be used to produce the coarse powder of the fineness of 10-60 meshes with a special accessory.

Working principle

In the main frame,a high pressure spring withan elasic force of 1000-1500 kg is fixed on the roller suspender.When the grinder mill is working, the roller will circumgyrate around the main shaft and squeeze the grinding ring strongly with a high pressure 1.2 degree than Raymond mill.When the stuff is loaded into the grinding cavity,it is shoveled into the space between the roller and the grinding ring.The grinded powder goes into the classifier along with the circulation wind generated by the blower. The standard fine powder is guided to the cyclone collector as the finish product while the others are sent back to the grinder for regrinding.The circulating airflow returns to the blower to repeat the above process and sends ashes into the dust cleaner for purification.

Equipment advantage

1.Compared with other pulverizers under the condition,the output of this high pressure grinder mill is increased by 20-30%.With the high pressure springs, ,the grinding pressure on raw mateaials can increase 800-1200kg.

2.All the mineral materials with the Mohs hardness below 9.3 can be crushed.

3.The finished powder has a wide range of particle size, from the maximum particle diameter of 0.613 mm(30 mesh)to the finest diameter of 0.013 mm(1000 mesh), and the normal particle diameter is about 0.033mm(425 mesh).

4.Its function of dust removing exactly meets the National Dust Discharge Standard.

5.The classifier is easy for adjustment.

6.The grinding unit adopts a superposition multi-grade sealing for better sealing performance.

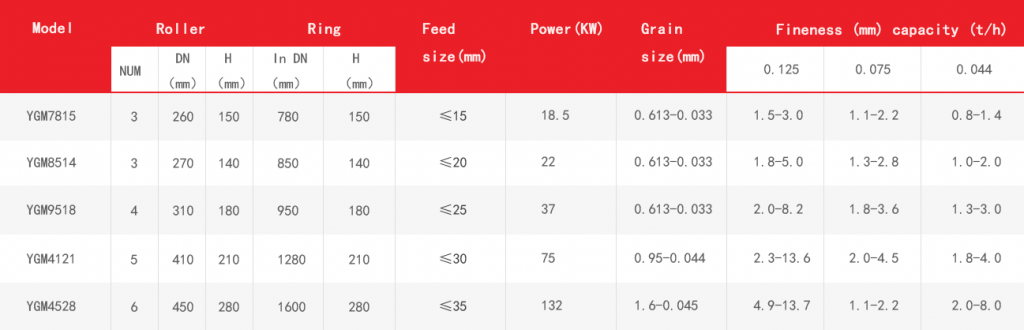

Product Parameter