Hitachi Reduced-Tail-Swing Excavator ZX135US-6

Product Feature

Engine

An Isuzu EPA Final Tier 4 (FT4)/EU Stage IV engine delivers fuel-efficient and reliable performance. Fuel pressure, timing and volume are precisely regulated by electronic control for efficient combustion with Isuzu’s common-rail fuel injection system.

The FT4 engine solution does not require a diesel particulate filter (DPF), saving service time and lowering operating costs.

Auto-idle, which reduces engine speed when hydraulics aren’t in use, and auto-shutdown contribute to fuel efficiency.

The pressurized fuel system improves fuel injector operation, and the fuel recirculation system helps prevent fuel gelling in cold climates – so you can maintain maximum productivity.

Durable structure and undercarriage

Thick-plate single-sheet mainframe, box-section track frames and industry exclusive double-seal swing bearing deliver rock-solid durability.

Thick-plate single-sheet mainframe, box-section track frames and industry exclusive double-seal swing bearing deliver rock-solid durability.

With large idlers, rollers and strutted track links, the sealed and lubricated undercarriage is built for the long haul.

With large idlers, rollers and strutted track links, the sealed and lubricated undercarriage is built for the long haul.

Tungsten-carbide-coated surfaces protect the critical bucket-to-arm joint.

Optional backfill blade adds stability and versatility, eliminating the need for another machine on the job.

Our FT4 field-proven technology is simple and efficient, employing cooled exhaust gas recirculation (EGR), a diesel oxidation catalyst (DOC) and selective catalytic reduction (SCR). An improved piston design allows particulate matter to be burned in cylinder, so there’s no need for a diesel particulate filter (DPF).

Optional rubber pad helps reduce damage when working on concrete or asphalt, and when crossing streets in residential developments.

Hydraulics

The ZX135US-6 comes with complete standard factory installed auxiliary hydraulics with programmable attachment modes and proportional control to help improve productivity on the jobsite.

It’s not always about brute force. Unmatched metering and smooth multifunction operation provide finesse and precision.

Stay on schedule with generous swing torque, digging force and lift capacity.

Muscle through tough digging by pressing the power-boost button.

Simple controls

Multi-language LCD monitor and rotary dial provide easy access to machine info and functions. Turn and tap to select work modes, monitor maintenance intervals, check diagnostic codes and set cab temperature. Control oil flow and toggle between dig and thumb modes with a programmable thumb attachment mode.

Multi-language LCD monitor and rotary dial provide easy access to machine info and functions. Turn and tap to select work modes, monitor maintenance intervals, check diagnostic codes and set cab temperature. Control oil flow and toggle between dig and thumb modes with a programmable thumb attachment mode.

Ergonomically correct short-throw pilot levers provide smooth, precise control with less effort. Standard sliding switch provides proportional speed control, giving you full command from your fingertips.

Ergonomically correct short-throw pilot levers provide smooth, precise control with less effort. Standard sliding switch provides proportional speed control, giving you full command from your fingertips.

Comfortable cab

Get unobstructed all-around visibility thanks to a wide expanse of front, side and overhead glass and mirrors, plus a standard rearview camera.

Get unobstructed all-around visibility thanks to a wide expanse of front, side and overhead glass and mirrors, plus a standard rearview camera.

Automatic, high-velocity bi-level climate-control system with automotive-style adjustable louvers helps keep the glass clear, the cab comfortable and the operator productive.

Operators get maximum support from a sculpted mechanical suspension high-back seat.

Easy to maintain

Easy-to-navigate LCD monitor tracks various fluid levels and issues scheduled maintenance alerts and diagnostic information.

Easy-to-navigate LCD monitor tracks various fluid levels and issues scheduled maintenance alerts and diagnostic information.

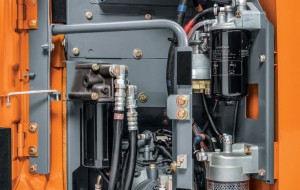

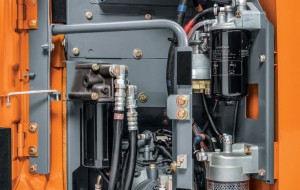

Engine oil, fuel and hydraulic pilot oil filters are all located on the same side at ground level for easy servicing.

Engine oil, fuel and hydraulic pilot oil filters are all located on the same side at ground level for easy servicing.

Easy-to-reach dipstick and see-through coolant reservoir make daily checks and/or additions quick and easy.

Easy-to-reach dipstick and see-through coolant reservoir make daily checks and/or additions quick and easy.

Ground-level-accessible coolers with easily removed pre-cleaner screens help prevent trash from plugging up the cores – helping maintain cool-running efficiency.

Ground-level-accessible coolers with easily removed pre-cleaner screens help prevent trash from plugging up the cores – helping maintain cool-running efficiency.

A battery disconnect switch, located in the rear door behind the cab, is easily accessible and extends battery life.

ZXLink™

The ZX135US-6 is standard equipped with Hitachi’s ZXLink™ system, giving you the power to monitor your fleet without ever leaving your seat through an easy-to-use website. Access fleet location, functions, hours, fuel consumption, alerts and other essential machine data. Know which machines are earning and which are idling – all while keeping preventive-maintenance tabs on each piece of equipment. View location and alert information with an app for iOS or Android devices. Plus, ZXLink can be set up to send alerts via email or text so you’re always in the know.

Product Parameter

| Emission Rating | Tier 4 |

| Number Of Cylinders (Per Engine) | 4 |

| Displacement | 3 ltr 182 Inches³ |

| Rated speed | 2000 rpm |

| Engine Output - Net | 75 kW 101 hp |

| Number Of Carrier Rollers - Each Side | 1 |

| Number Of Track Rollers - Each Side | 7 |

| Track Shoe Width | 700 mm 28 inches |

| Transport Length Mono Boom | 7390 mm 24 ft 3 in ft/in |

| Transport Height - Maximum | 2870 mm 9 ft 5 in ft/in |

| Overall Undercarriage Width | 2690 mm 8 ft 10 in ft/in |

| Track Length On Ground | 2880 mm 9 ft 5 in ft/in |

| Undercarriage Overall Length | 3580 mm 11 ft 9 in ft/in |

| Tailswing Radius | 1490 mm 4 ft 11 in ft/in |

| Ground Clearance | 410 mm 16 inches |

| Width over standard tracks | 2690 mm 8 ft 10 in ft/in |

| Track Gauge | 1990 mm 6 ft 6 in ft/in |

| Digging Reach - Mono Boom | 8860 mm 29 ft 1 in ft/in |

| Ground Level Reach - Mono Boom | 8720 mm 28 ft 7 in ft/in |

| Dig Height - Mono Boom | 9690 mm 31 ft 9 in ft/in |

| Dump Height - Mono Boom | 7220 mm 23 ft 8 in ft/in |

| Dig depth - 2.44m / 8'ft flat bottom | 5790 mm 19 ft ft/in |

| Dig Depth - Mono Boom | 5980 mm 19 ft 7 in ft/in |

| Fuel Tank | 220 ltr 58 gallons (US) |

| Hydraulic Tank | 60 ltr 15.9 gallons (US) |

| Ground Bearing Pressure | 32 kPa 4.64 PSI |

| Dipper Tearout | 61 kN 13710 lbf |

| Operating Weight | 14300 kg 31500 lbs |